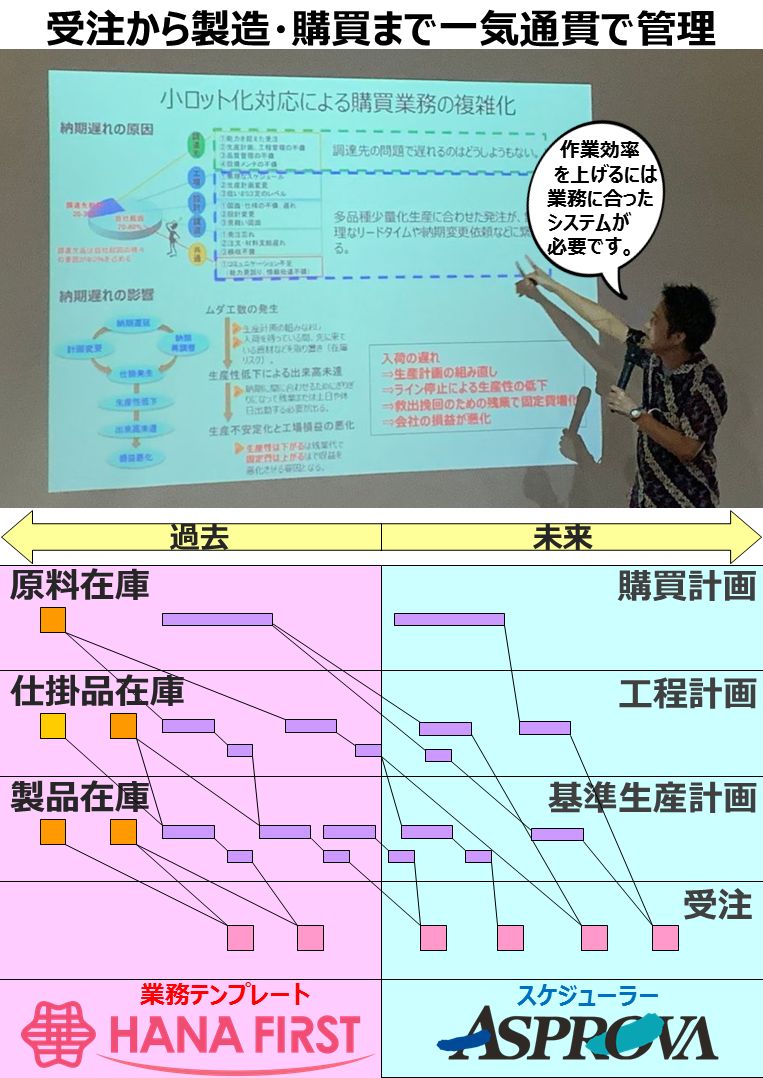

All internal operations are tied to the company’s revenue—the source of cash inflow—and procurement—the source of cash outflow. Due to three problems—lack of visibility into the current situation, numbers not aligning, and processes not connecting—operational efficiency declines, and employees’ awareness of sales and cost management diminishes. Production Control System in Indonesia It’s not limited to Indonesia, but it’s often said that the ultimate goals of the manufacturing industry are twofold: "cost reduction through productivity improvement" and "delivering products on time without delays." From a management perspective, business plans are crafted to maximize growth based on market supply and demand adjustments. However, even if sales increase due to low pricing, it only reduces gross profit, leading to losses from selling and administrative expenses or non-operating costs. On the other hand, raising unit prices isn’t straightforward due to market price considerations. Therefore, process management based on production plans aimed at reducing costs through ... 続きを見る

What Factors Influence Internal Operations in Indonesian Factories?

Having worked on business systems in Indonesia for a long time, the issues with business systems that come up in conversations with Japanese companies’ clients can generally be summarized into the following three points:

- It’s unclear which shipments the goods flowing through the business process are linked to.

- Forcing operations to fit a mismatched system results in extensive Excel-based management intervening.

- Disconnected workflows between departments lead to excessive manual adjustments outside the system.

All internal operations are connected to revenue (shipments), the source of cash inflow, and procurement, the source of cash outflow. This trio of issues—lack of visibility, mismatch, and disconnection—reduces operational efficiency and leads to a decline in employees’ sales and cost awareness.

A company’s business is determined by what it offers to meet market needs, and internal operations are shaped by how it interacts with customers and suppliers and how internal staff collaborate.

Specific examples of factors determining internal operations include:

- As the number of customers grows but order sizes shrink, it becomes unclear on-site which orders production is for, making delivery date responses impossible.

- Shortened product lifecycles and harder demand forecasting mean ordering and producing only what’s needed for orders to avoid dead stock.

- Overthinking point 2 and keeping too little inventory leads to line stoppages, reducing productivity and delaying deliveries.

- With multi-variety, small-lot production flowing through lines, increasing shared line usage and uptime requires clear order linkage—otherwise, excess production occurs.

- In Indonesia, suppliers and subcontractors hold strong influence, requiring orders with sufficient lead time based on accurate demand forecasts.

- Indonesia’s low local procurement rate makes shortages of imported materials critical.

Business systems should be defined by these internal operation methods. Changing the operation methods determined by various factors for systemization can be seen positively as standardization or negatively as inconsistent directives.

Economic Activity Occurs on the Supply Chain

In manufacturing, raw materials are procured, processed to add value, and sold to customers. In services, value is added by providing services based on customer requests.

When procuring goods, suppliers are upstream, and when selling goods or services, customers or consumers are downstream. The route through which goods and information flow from suppliers through the company to customers or consumers is called the supply chain.

Economic activity is the aggregation of actions that move goods and services along this supply chain. Simply siphoning money off the supply chain without adding value isn’t economic activity.

Economic activity isn’t completed by a single company alone—it’s sustained by promises and results with suppliers, customers, and consumers. It’s evaluated by metrics like “reliability” (delivering the promised quantity with promised quality on time), “flexibility” (quickly adapting to customer or market demand changes to seize sales opportunities), and “responsiveness” (shortening lead time from order to shipment).

Within relationships with trading partners and customers, optimizing business flows to enhance reliability, flexibility, and responsiveness is called the Standard Operation Procedure (SOP). Gaining ISO certification as proof of meeting certain standards builds trust along the supply chain.

Operational Methods Are Determined by Relationships with Suppliers and Partners on the Supply Chain

Generally, there are two main approaches to introducing business systems for companies conducting economic activity on the supply chain, both in Japan and Indonesia:

- Systemization assuming company operations align with a packaged system’s workflow.

- Systemization tailored to the company’s unique operational flow.

As of 2019, the mainstream approach is standardizing company operations by aligning them with the workflows of packaged systems—culminations of developers’ expertise. However, this often results in an underwhelming outcome: “The system is running, but it’s not delivering cost-effectiveness.”

- The system is used solely for the core functions of master and inventory management among the packaged system’s features.

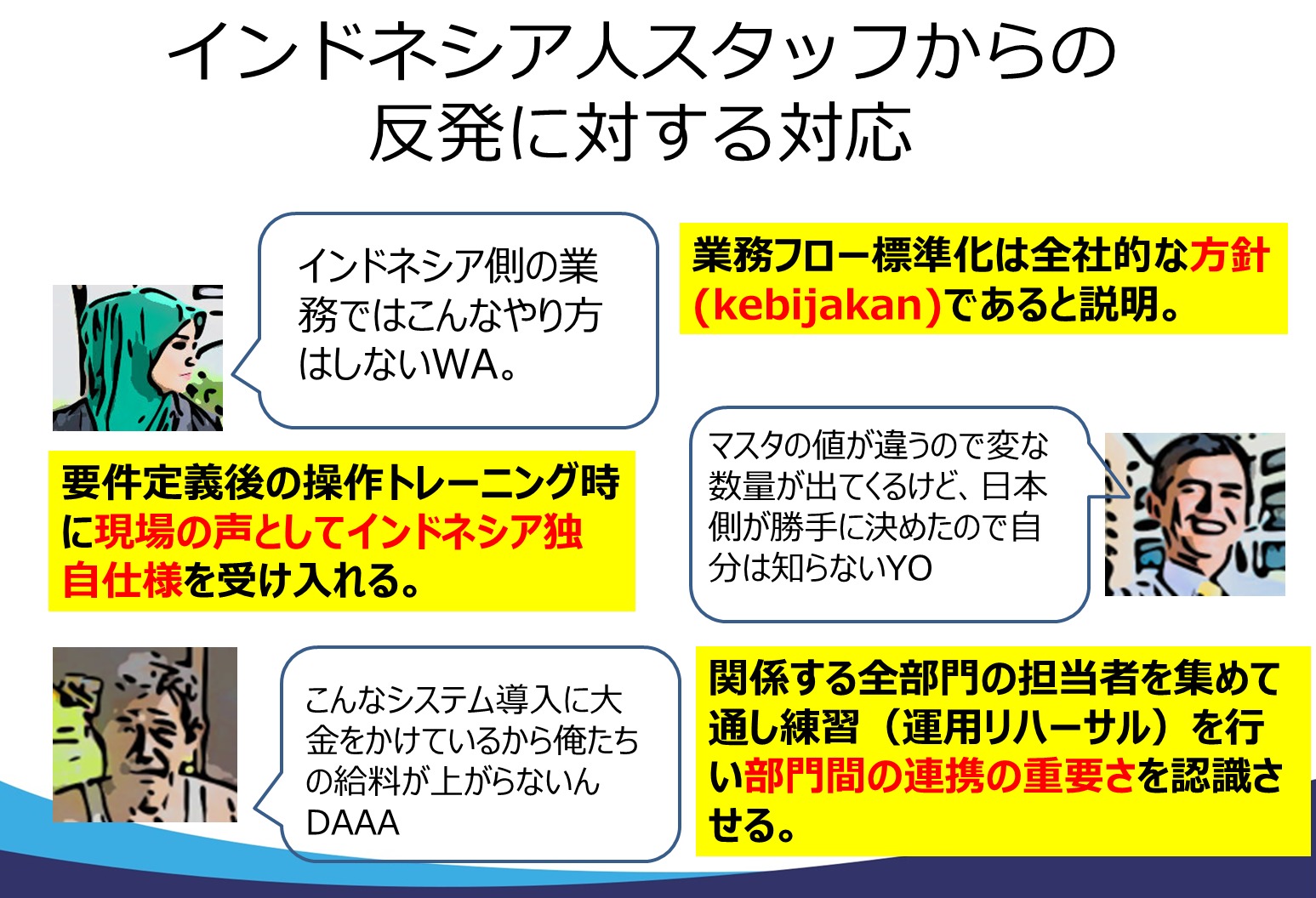

- Despite introducing it to align with the standard flow, halfway customizations creep in due to on-site pushback.

Introducing a packaged system involves three main phases: requirements definition, implementation (development), and on-site deployment (training). Aligning operations with the system minimizes implementation (development) efforts, focusing the requirements definition phase on “how to adapt operations to the package’s specs.” This works under conditions like:

- Few daily production batches or purchase orders, meaning low transaction volume.

- ⇒ Low system input burden.

- ⇒ Sufficient time for training.

- ⇒ High system inventory accuracy, reducing adjustment efforts.

- Clear operations where suppliers deliver based on orders, or customers receive shipments based on orders.

- ⇒ Order backlog management is recognized as critical, avoiding inventory-only operations.

- Few suppliers and customers.

- ⇒ Fewer data format types, reducing import burdens.

Since internal operations are shaped by relationships with suppliers and partners on the supply chain, for most companies not meeting these “fortunate” conditions, aligning operations with a system is highly challenging.

When aligning with a package is difficult, steady work is needed: developing and implementing the system based on requirements definition, then fine-tuning specs during on-site deployment by incorporating requirements missed earlier.

Systemizing Internal Operations in Indonesia’s Excel-Driven Culture

Standard workflows in major packaged software like SAP or Microsoft Dynamics are accumulations of vendors’ decades of expertise. Operations not aligning with these are considered flawed, and adapting to the system’s flow is seen as the shortest path to efficiency—a common view when considering system導入 in Japan.

This is a valid option in an environment where goods flow smoothly between customers and suppliers per contracts, all transaction info is reflected in the system, and company decisions are made by deductively analyzing system-stored data.

However, in Indonesia—where internal decisions are swayed by individual or departmental politics, or supply chain constraints complicate customs with customers, suppliers, and subcontractors—operations take on a unique culture. As stakeholders seek the easiest methods, the result is a collection of localized optimizations.

Excel becomes a prized patch to connect these localized optimizations. While the overall operation features Excel patchwork, it inadvertently aims for global optimization.

To systemize such operations in Japanese companies in Indonesia, it’s more logical to extract critical requirements from Excel-patched, interconnected workflows and implement a system tailored to them.

In an environment where goods flow smoothly on the supply chain and all transaction info is system-reflected, major packaged software might be the best practice. But in Indonesia’s less ideal environment, diligently gathering requirements and implementing them steadily yields more visible improvements.

- Efficiency improved by using a customized system for operations unaddressed by generic packages.

- Short-term plan adjustments for order delivery or quantity changes became possible, maintaining high plan accuracy.

- Process performance became visible on large on-site monitors.

- Warehouse in-out management with handheld terminals auto-linked easily to the inventory system.

- Attaching order-numbered tags to flowing lots made physical goods and system inventory connections visible.

- Monthly production planning, once taking a week, now takes 3 hours.

- Linking orders and procurement clarified this month’s raw material needs, eliminating line stoppages from shortages.

- Complex production plans (color, spec, day summaries) unfeasible in Excel are now quickly created.

- Higher demand forecast accuracy reduced excess production and in-process inventory.

Thus, in Indonesia, developing and implementing systems tailored to operations offers significant potential for efficiency gains.

Reasons for Considering Production Management System導入 in Indonesia

System investment in Indonesia became a focus as Indonesian factories grew in importance, demanding accurate, rapid info management and effective info use. Broadly, it’s driven by Japan HQ requests or local Indonesian needs:

- Reduce operational burden with company-wide unification.

- Enable data monitoring from Japan.

- Link data to Japan’s system.

- Align with Japan’s rules (inventory valuation, form fields, etc.).

- Low data accuracy.

- Slow data entry.

- High data entry burden.

- Insufficient necessary data (forms).

- Entered data isn’t effectively utilized.

Issues with Japan-Led vs. Indonesia-Led System導入

Japan-led systemization often occurs in larger firms, driven by Japan HQ requests. The same system as Japanese factories is introduced with support from HQ’s IT department, but issues arise: inability to master expensive systems, disuse after HQ staff return, inaccurate data input, and unmaintained masters.

Japan-led systemization often occurs in larger firms, driven by Japan HQ requests. The same system as Japanese factories is introduced with support from HQ’s IT department, but issues arise: inability to master expensive systems, disuse after HQ staff return, inaccurate data input, and unmaintained masters.

Indonesia-led systemization typically occurs in smaller firms, with factories independently selecting systems. Not all operations unify under one system, often leaving some Excel management. Issues include duplicate entries, disconnected system workflows, and person-dependent systems.

The requirements definition phase—reviewing current operations and deciding system integration—splits into three patterns in Indonesia:

Complete Japan-led is “Perintah langsung” (direct orders from the top), deploying HQ specs locally. Local majority rule is “Pengambilan suara” (voting), where departmental power dynamics affect specs, making a local coordinator key. “Musyawarah” (consensus) seeks unanimous agreement through discussion.

Indonesian National Traits to Consider in Production Management System導入

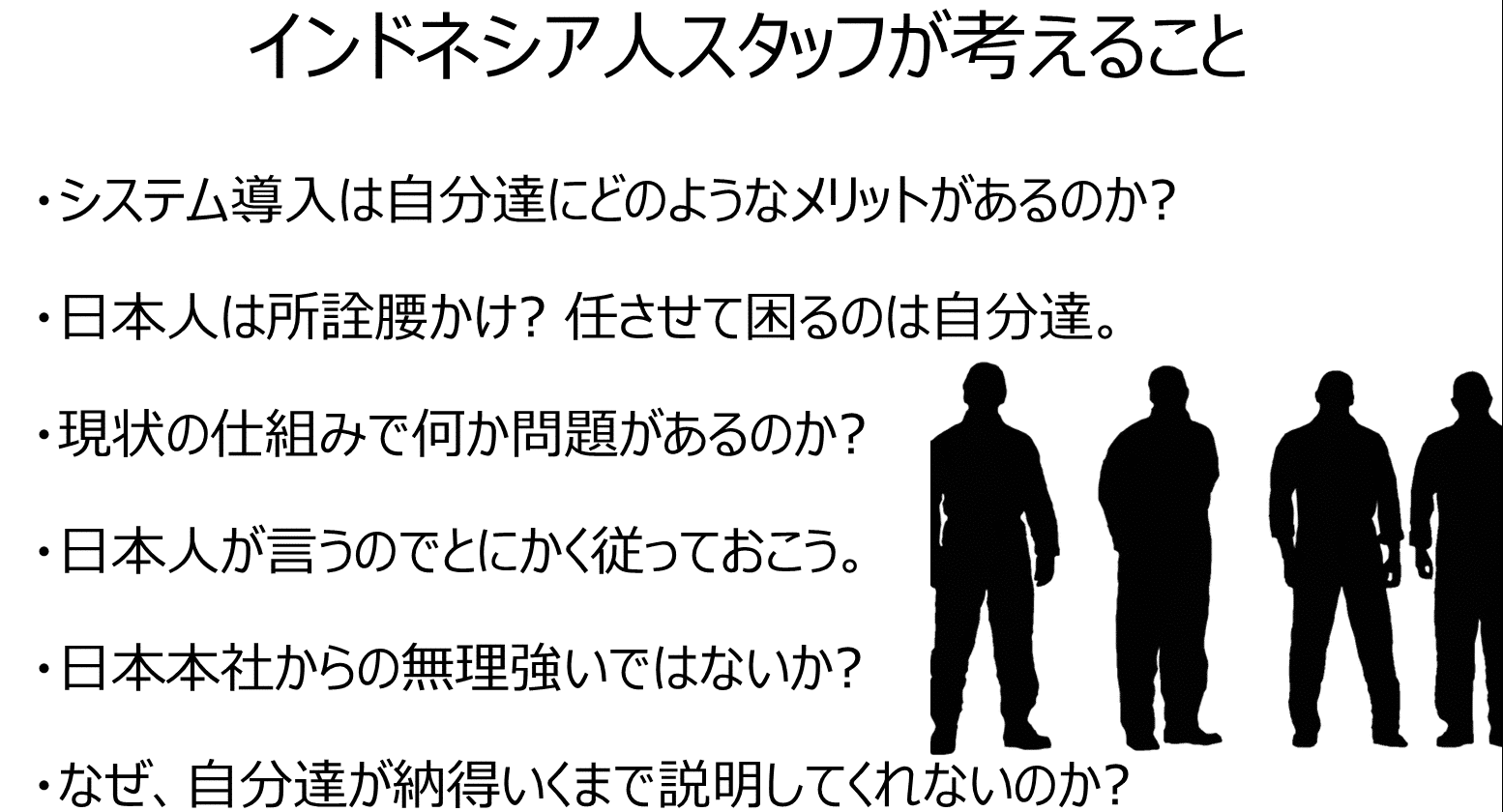

In the 1990s, Japan’s famed management trifecta—lifetime employment, seniority, and company unions—waned amid rising competition from China and Asia. Yet, the lingering Japanese habit of leaving decisions vague (“aun no kokyu”) clashes with Indonesian office workers accustomed to clear American-style job descriptions, causing communication issues with Japanese expatriates and HQ.

Local staff at overseas Japanese firms likely share similar thoughts: “Why don’t they explain until we’re satisfied?”—a phrase I’ve heard repeatedly in Indonesia’s system導入 sites.

A Stepwise System導入 Method Suited to Indonesia

For years, I firmly believed that forcing non-customized packaged software as the standard workflow was the most effective approach for system導入 in Indonesia.

Recently, I realized the obvious: if the gap between new and current workflows is too wide, Indonesian staff grow skeptical of results and emotionally resist, even if the system is standardized.

For example, if current operations confirm 50 out of 100 results before proceeding to the next 50, but a new system instantly outputs 100 with slightly different results, staff doubt it—even if it’s more accurate.

Though the new system can output 100 directly, we deliberately use an external add-on to replicate the current process for 0–50, letting staff verify results, then implement 51–100 with the system’s functions.

Systemization aims to improve current operations, but replacing the exact same flow offers little gain. More importantly, we prioritize users’ feelings—making “the process behind system results visible”—focusing on add-on user support rather than package customization.

What’s a Business System Suited to Indonesia?

To address Indonesia’s visibility, mismatch, and disconnection issues, we must extract key requirements from operations shaped by unique internal cultures and implement them steadily in the system.

Rather than scratch-building everything, common system functions—user permissions, master data management, Excel/CSV export/import, transaction tracking, and closing processes—can be standardized.

Pardon the self-promotion, but our company uses HanaFirst for management functions and Asprova for scheduling—a best practice I propose to Japanese firms in Indonesia after 20+ years in the system industry.

Systems are a means to achieve business improvement, enhancing data entry efficiency and accuracy, and enabling effective info use through visualization, sharing, and systematization—turning on-site data into competitive strength.

To deliver visible results, we thoroughly hear customer requirements and focus on proposing systems that show how much operations improved and what new outcomes emerged.