We propose a production management approach that combines the pull-type kanban method, which excels at autonomous production adjustments at Indonesian manufacturing sites, with a push-type production scheduler that issues production instructions in response to demand fluctuations. Production Control System in Indonesia It’s not limited to Indonesia, but it’s often said that the ultimate goals of the manufacturing industry are twofold: "cost reduction through productivity improvement" and "delivering products on time without delays." From a management perspective, business plans are crafted to maximize growth based on market supply and demand adjustments. However, even if sales increase due to low pricing, it only reduces gross profit, leading to losses from selling and administrative expenses or non-operating costs. On the other hand, raising unit prices isn’t straightforward due to market price considerations. Therefore, process management based on production plans aimed at reducing costs through ... 続きを見る

Changes in Indonesian Manufacturing Sites During the COVID-19 Pandemic

Indonesia’s automobile production in April dropped by 80% compared to the same month the previous year. For the next one to two years until a COVID-19 vaccine is developed, it’s likely that production will be driven by demand fluctuations.

Additionally, some factories have started producing masks, shields, ventilators, and other products different from their usual offerings, making process leveling increasingly difficult. The demands to address shortages and excess inventory are likely higher than ever before.

While predictable demand fluctuations might have been manageable with the intuition of experienced workers, unprecedented demand fluctuations may be difficult to handle with intuition alone.

Beyond COVID-19, natural disasters and other factors have disrupted material supply, and it seems that every year, issues arise not only within the company but also with suppliers.

In Indonesia, where Toyota vehicles are prevalent, many factories adopt Toyota’s kanban production system. However, aren’t some managers feeling uncertain about whether kanban is still circulating as smoothly as before?

The situation at production sites appears to be changing in the following ways:

- With unprecedented demand fluctuations and the need to produce new products, relying solely on the intuition of experienced workers is becoming difficult.

- If workers are inexperienced, progress becomes inconsistent, requiring flexible responses.

- While kanban has been an effective tool for production adjustments, the preconditions for its operation are starting to erode.

When demand fluctuations are significant, monthly leveling becomes challenging, and operating solely with pull-type kanban has its limitations, increasing the need for push-type production instructions aligned with demand fluctuations.

However, with push-type production instructions, unconditionally producing the instructed amount can lead to the issue of "overproduction".

Therefore, we believe there is a need for a hybrid production method that flexibly instructs production quantities per process in response to demand fluctuations while using kanban adjustments to prevent overproduction.

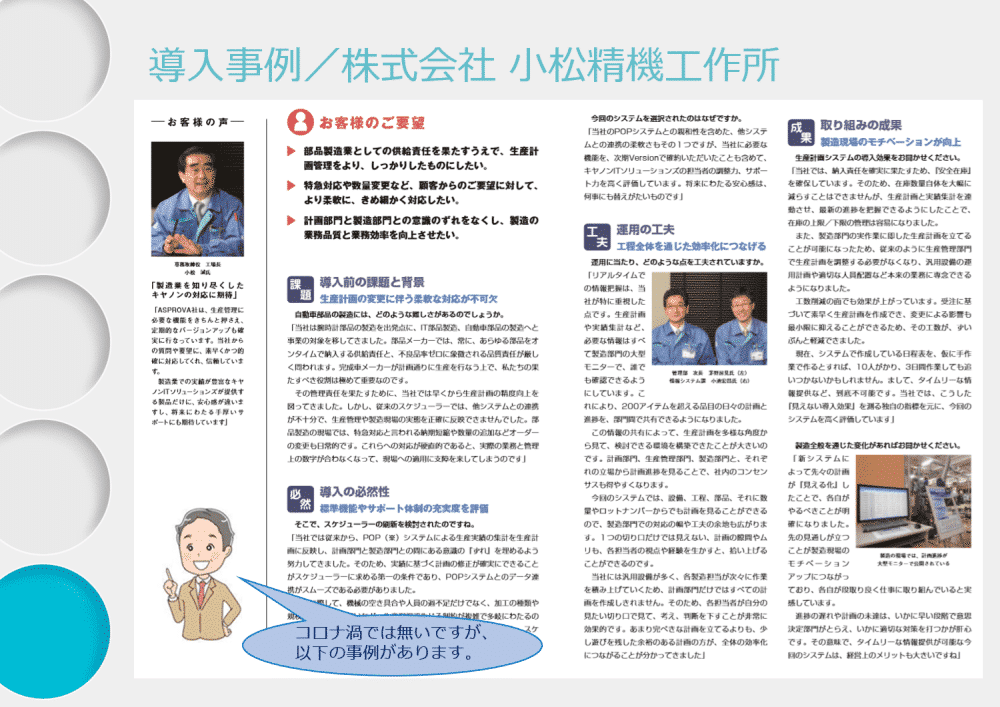

Case Study: Komatsu Seiki Kosakusho Co., Ltd.

During the COVID-19 crisis, I believe information sharing and collaboration are critical. With various pieces of information changing, determining which tasks are affected and whether immediate action is needed requires objective judgment metrics.

While this case study isn’t from the COVID-19 period, it highlights that early detection expands response options. Thus, isn’t how quickly issues are noticed and communicated to relevant departments a key system requirement in today’s high-demand fluctuation environment?

Recently, news of secondary infection clusters in food factories in Germany and China suggests this isn’t someone else’s problem. To avoid the "three Cs" (closed spaces, crowded places, close-contact settings), factories should minimize unnecessary on-site adjustments as part of non-essential measures. For instance, running around the site to find materials due to shortages or repeatedly adjusting plans with the site using manpower should be reduced.

For this reason, systems that allow adjustments without going to the site are shifting from a necessity to a must-have. For example, during the Thailand floods, factories promoted BCP (Business Continuity Plan) flood countermeasures; similarly, during the COVID-19 crisis, presenting BCP measures for the pandemic is likely to be demanded.

【Key Points of the Case Study】

- Improve planning accuracy to ensure reliable parts supply to manufacturers.

- Respond flexibly to urgent items, delivery changes, and quantity adjustments.

- Eliminate discrepancies among purchasing, planning, manufacturing, and sales departments to enhance operational efficiency.

- Issues included inflexibility in handling frequent urgent items, delivery changes, and quantity adjustments, as well as discrepancies between actual operations and numerical data.

- Introducing performance input (POP) required improving planning accuracy to bridge the gap between planning and manufacturing.

- The machinery department needed to address equipment availability, staffing shortages or surpluses, process differences due to machining types, and a wide range of constraints.

- Daily plans and progress for items became shareable across departments, allowing planning, production management, manufacturing, and sales departments to monitor progress from their respective perspectives.

- Installing large monitors on-site enabled viewing from perspectives like equipment, processes, parts, and orders, reportedly creating more response options and flexibility.

-

- While setting high safety stock levels to avoid shortages didn’t drastically reduce inventory, linking plans with performance maintained a consistent inventory level. Reduced manual coordination between departments increased flexibility and motivation in each department.

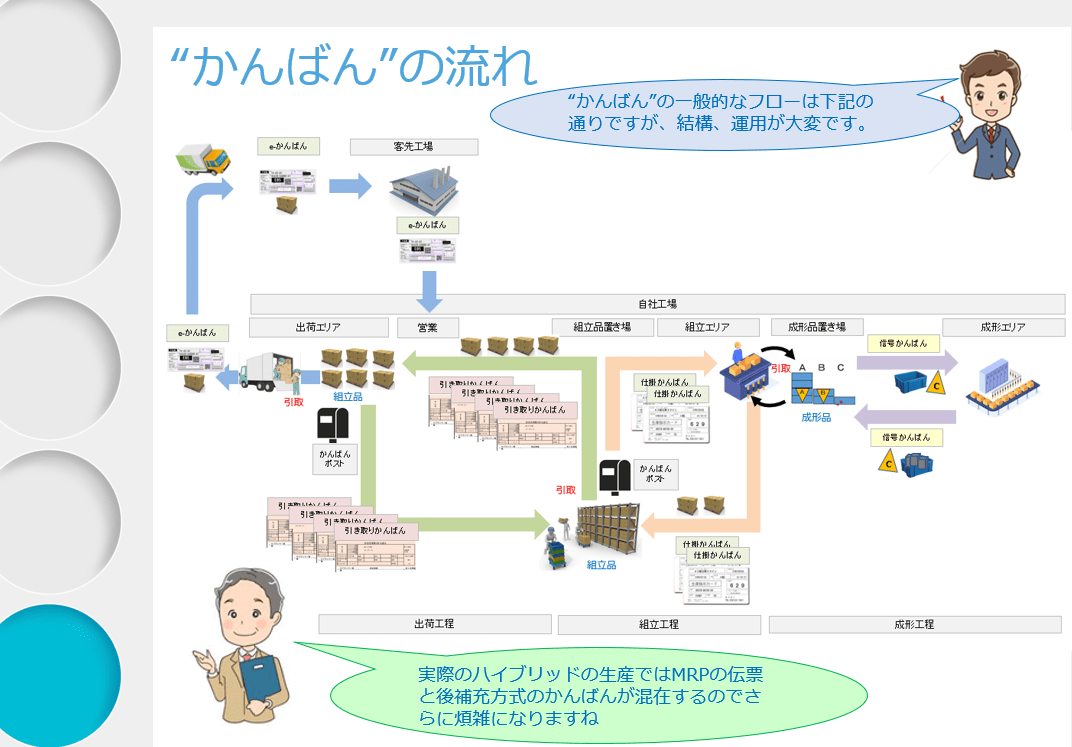

Kanban Method Operation Flow in Indonesia

This is a general flow of the kanban system: e-kanban from customers is swapped with pickup kanban inserted in boxes at the shipping area. Once a set number of pickup kanban accumulates at the kanban post, it is swapped with in-process kanban inserted in boxes at the assembly storage area, and the boxes are pulled to the shipping area. When a set number of detached in-process kanban accumulates at the kanban post, it is returned to the assembly area as work instructions.

For lot production processes like molded items, signal kanban serves as work instructions to the molding area when intermediate inventory at the storage area falls below the MIN level. This is a typical kanban flow, characterized by no underproduction or overproduction as the site autonomously adjusts for shortages.

Even in factories using the kanban method, if upstream processes like molding or pressing differ significantly in takt time or lot size from downstream assembly processes, there are cases where Asprova is introduced for upstream processes with MRP-based work instructions, while downstream processes operate solely with kanban.

Moreover, with numerous molding or pressing machines, decisions about which equipment to use and how to minimize setups require equipment allocation plans considering production efficiency, an area where kanban alone may struggle to issue work instructions.

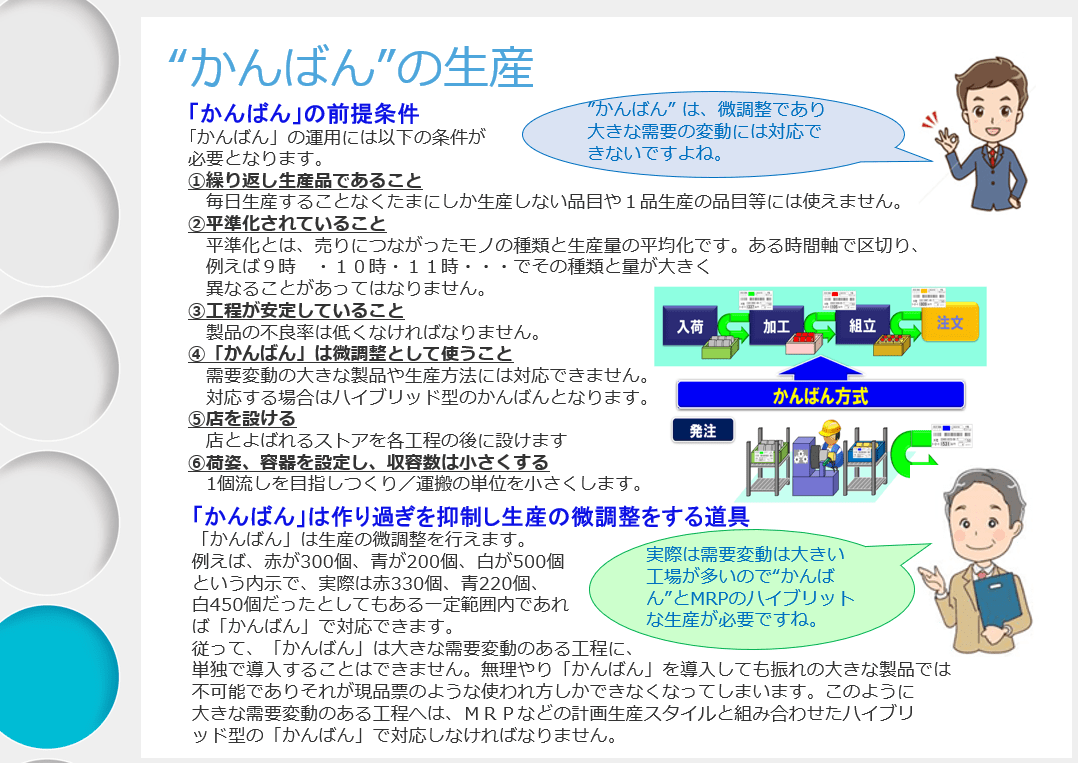

Levelized Production as the Core Premise of the Kanban Method

The kanban method requires leveled work times between processes. Since kanban card counts are determined based on monthly production volume, it assumes daily demand fluctuations are managed with minor adjustments. Thus, depending on the factory, isn’t it becoming harder to operate kanban as before amid significant daily demand fluctuations during the COVID-19 crisis?

The kanban method requires leveled work times between processes. Since kanban card counts are determined based on monthly production volume, it assumes daily demand fluctuations are managed with minor adjustments. Thus, depending on the factory, isn’t it becoming harder to operate kanban as before amid significant daily demand fluctuations during the COVID-19 crisis?

Implementing the kanban method requires several conditions:

- Repetitive production

- Levelized production items

- High and stable production yield

- Low demand fluctuations

- Storage areas after each process

- Minimal box capacity

The kanban method produces only what is needed in the required quantity. Ideally, box capacity should be minimized, aiming for one-piece flow, but considering machine production speed and site efficiency, a certain box size is set.

In practical operations, producing per box unit may reduce productivity, so some factories set local rules, such as starting production only after several kanban cards accumulate after detachment.

Calculating kanban card counts amid demand fluctuations is challenging, and adjusting the accumulation of kanban cards based on local rules may further complicate operations.

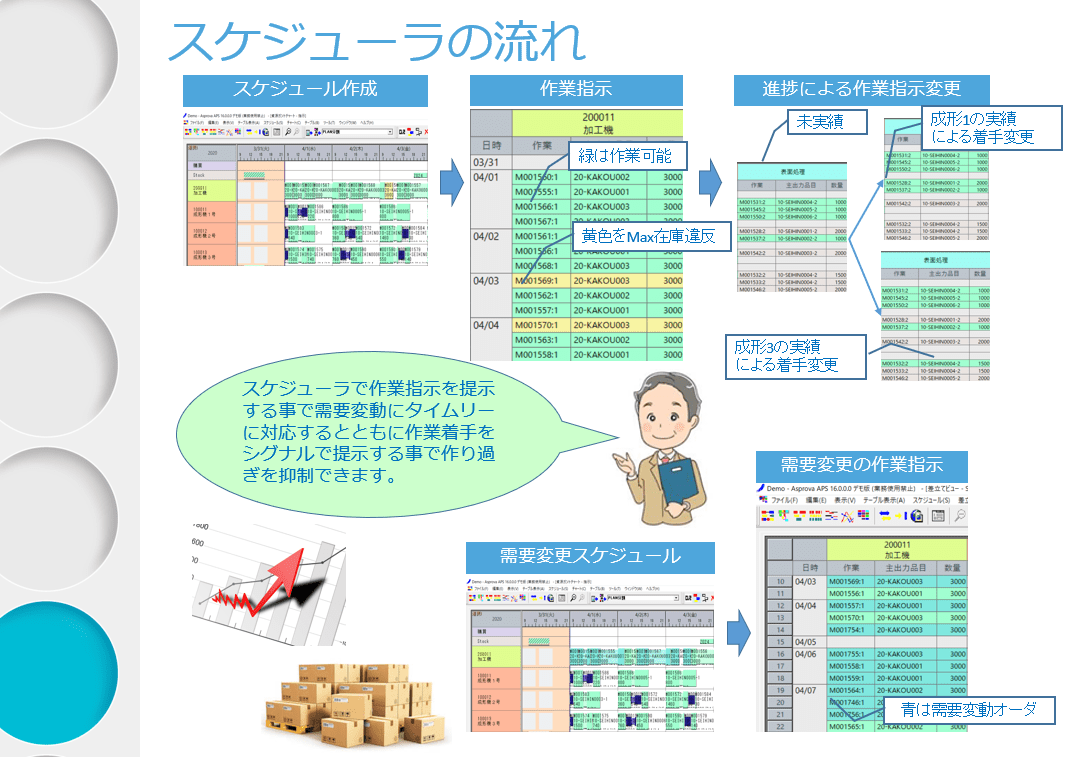

Production Scheduler Operation Flow in Indonesia

So far, we’ve discussed challenges at production sites during the COVID-19 crisis. Specifically, how does a scheduler operate? It issues appropriate work instructions aligned with demand while displaying own-process tasks in green when upstream tasks are completed, indicating they are ready to start.

So far, we’ve discussed challenges at production sites during the COVID-19 crisis. Specifically, how does a scheduler operate? It issues appropriate work instructions aligned with demand while displaying own-process tasks in green when upstream tasks are completed, indicating they are ready to start.

Additionally, tasks exceeding MAX inventory are displayed in yellow to halt work, enabling production timing adjustments at the site similar to kanban. By signaling upstream and downstream conditions, it clarifies what to produce next, facilitating early preparation and expanding options for consolidated production.

The scheduler can also timely adjust equipment reassignments due to demand fluctuations and task sequence changes based on material delivery status.

While kanban often adjusts card counts based on monthly demand, a scheduler with MRP functionality can calculate kanban card counts in response to demand fluctuations. If monthly demand can be leveled, Asprova can calculate kanban counts, but kanban may struggle to respond to daily demand fluctuations or assess their impact on departments.

In some factories, managing multiple instructions like in-process kanban, pickup kanban, and MRP-based work instructions may complicate operations.

Using a scheduler to consolidate instructions into a single sheet and automatically manage kanban detachment based on upstream and downstream conditions could simplify operations.

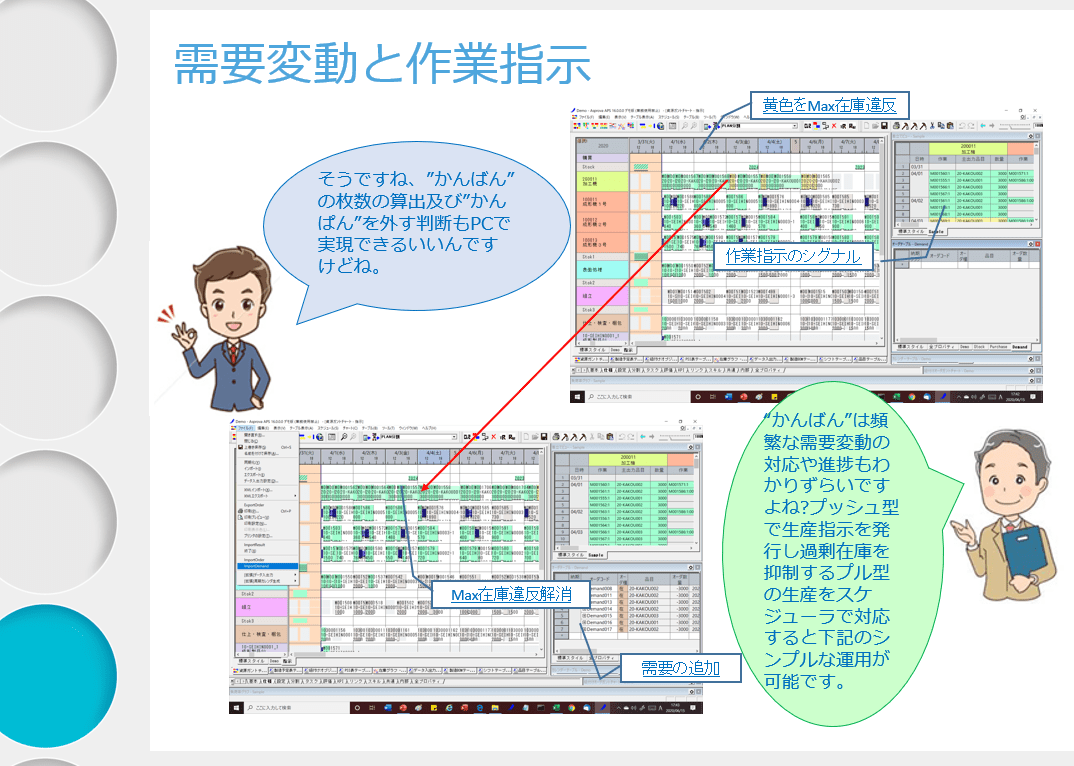

Production Scheduler Response to Demand Fluctuations

In practice, how a scheduler responds to demand fluctuations: if a simple variance in shipment volume occurs, it automatically adjusts the work instruction quantity.

For example, if demand increases, work instructions are added; if equipment load increases and start dates are delayed due to added instructions, tasks previously halted by MAX inventory turn green and become startable, updating all related information. Since the scheduler operates with a single instruction sheet, all information is centralized, streamlining management.

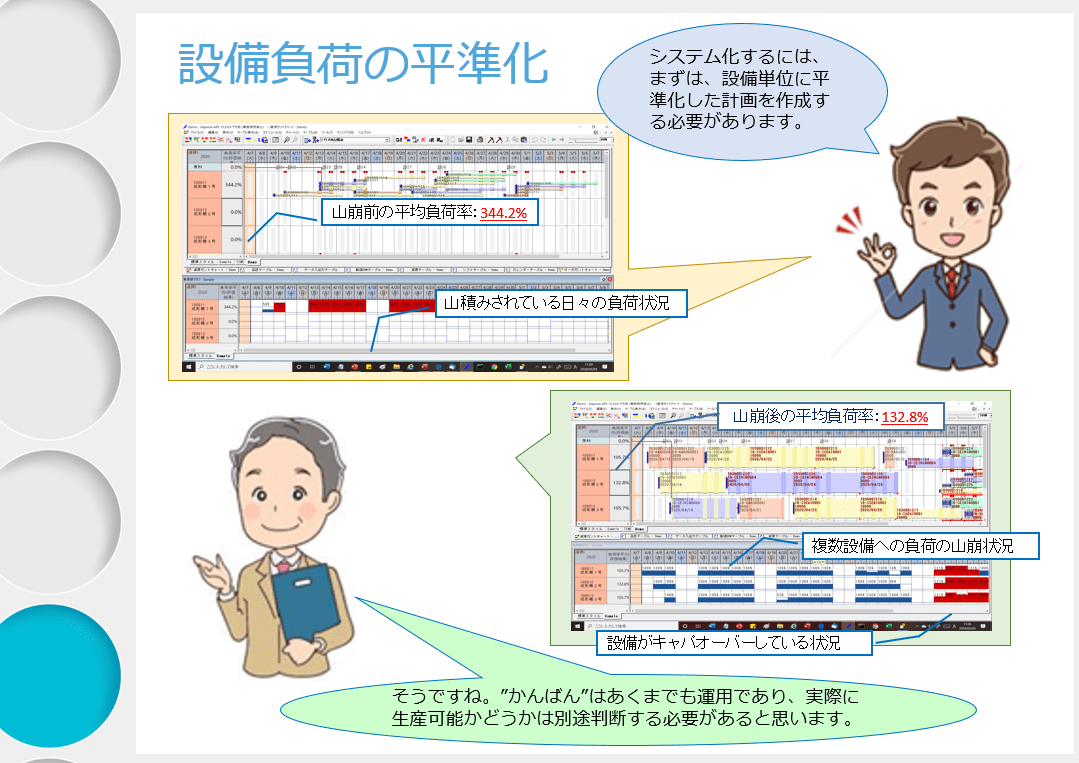

Equipment Load Leveling

The greatest advantage of Asprova is leveling equipment load and assigning tasks, something kanban cannot handle alone. Since kanban is a site operation method, determining production feasibility in advance requires a separate tool, a role the scheduler can fulfill.

The greatest advantage of Asprova is leveling equipment load and assigning tasks, something kanban cannot handle alone. Since kanban is a site operation method, determining production feasibility in advance requires a separate tool, a role the scheduler can fulfill.

In fact, some factories using Asprova schedule with it before operating kanban to assess whether production between processes is leveled, equipment capacity is sufficient, and overtime is unnecessary.

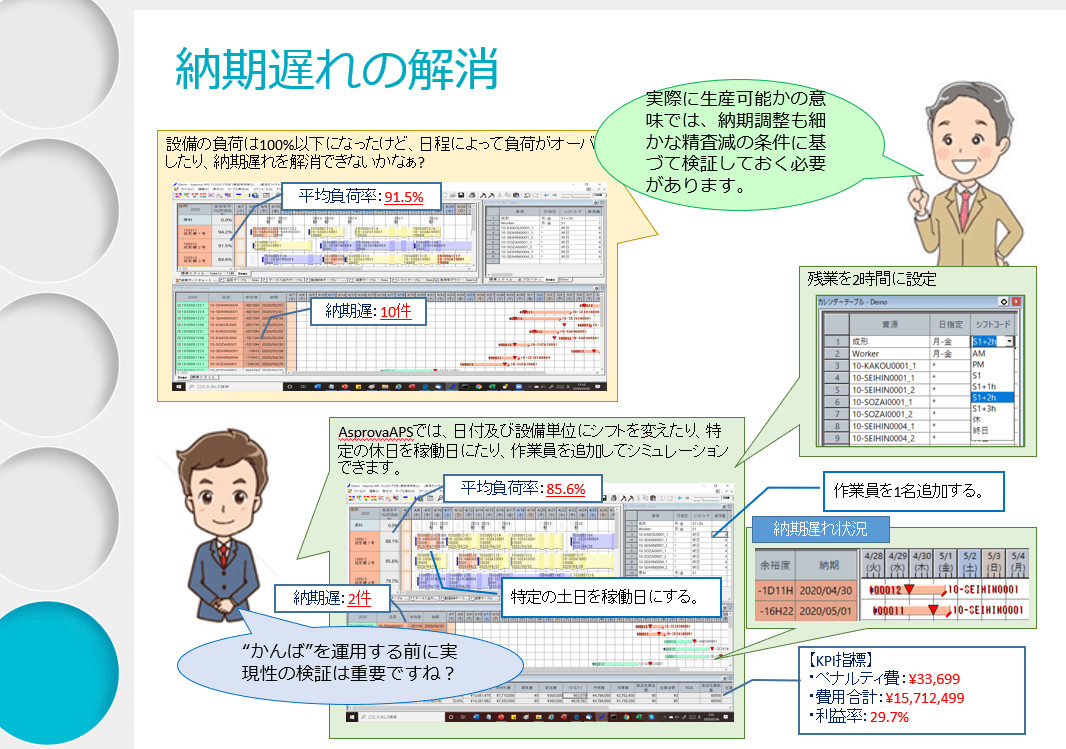

Eliminating Delivery Delays

Even when operating with kanban, verifying feasibility at the production site is crucial. Once in operation, kanban runs autonomously, so confirming in advance whether demand can be produced without delays requires setting conditions and simulating with a scheduler.

Even when operating with kanban, verifying feasibility at the production site is crucial. Once in operation, kanban runs autonomously, so confirming in advance whether demand can be produced without delays requires setting conditions and simulating with a scheduler.

In processes with dozens of molding or pressing machines, numerous equipment constraints like molds, jigs, and workers necessitate equipment allocation planning.

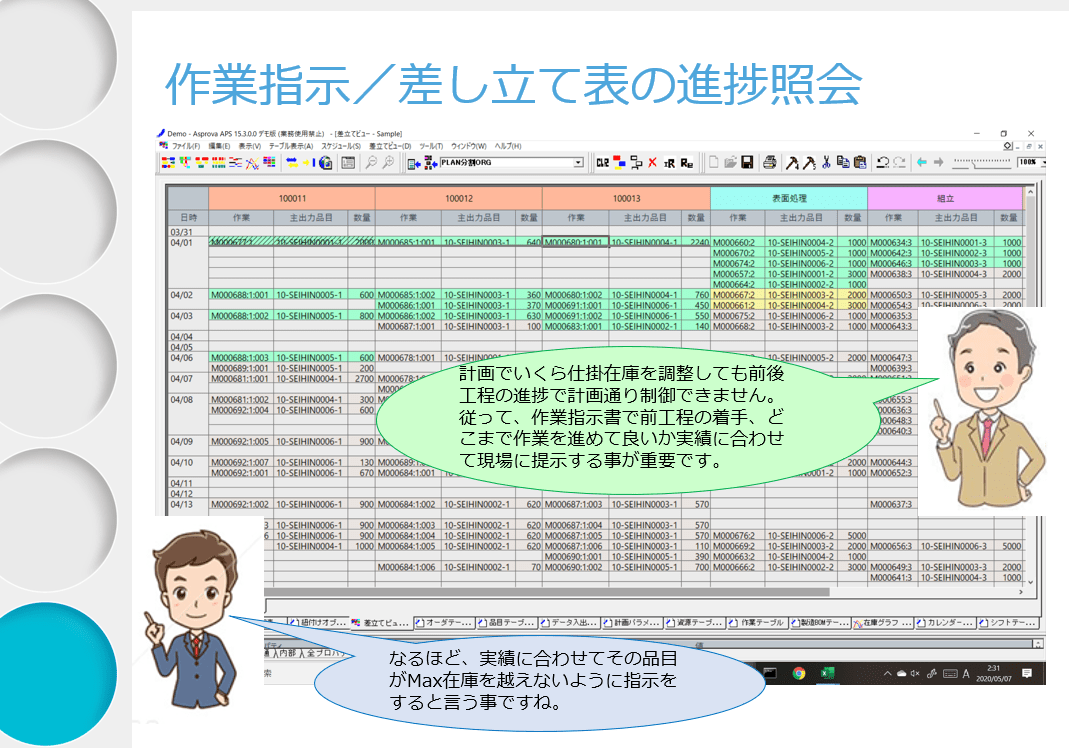

Work Instructions/Progress Directive Sheet

Green indicates upstream completion, yellow indicates pending due to exceeding MAX inventory, and gray indicates upstream tasks yet to start, allowing work start adjustments while monitoring upstream and downstream progress. No matter how much in-process inventory is adjusted in planning, delays in upstream or downstream progress prevent plan-based control.

Thus, presenting to the site via work instructions when upstream tasks start and how far to proceed based on performance is critical.

This involves issuing instructions to ensure an item does not exceed MAX inventory based on performance. By checking startable tasks upon upstream completion, it determines which tasks to consolidate for production (kanban card accumulation at the kanban post) as per kanban local rules before kanban circulates, based on upstream task completion.

Early detection enables proactive preparation (promoting external setup) and expands options for efficient task consolidation.

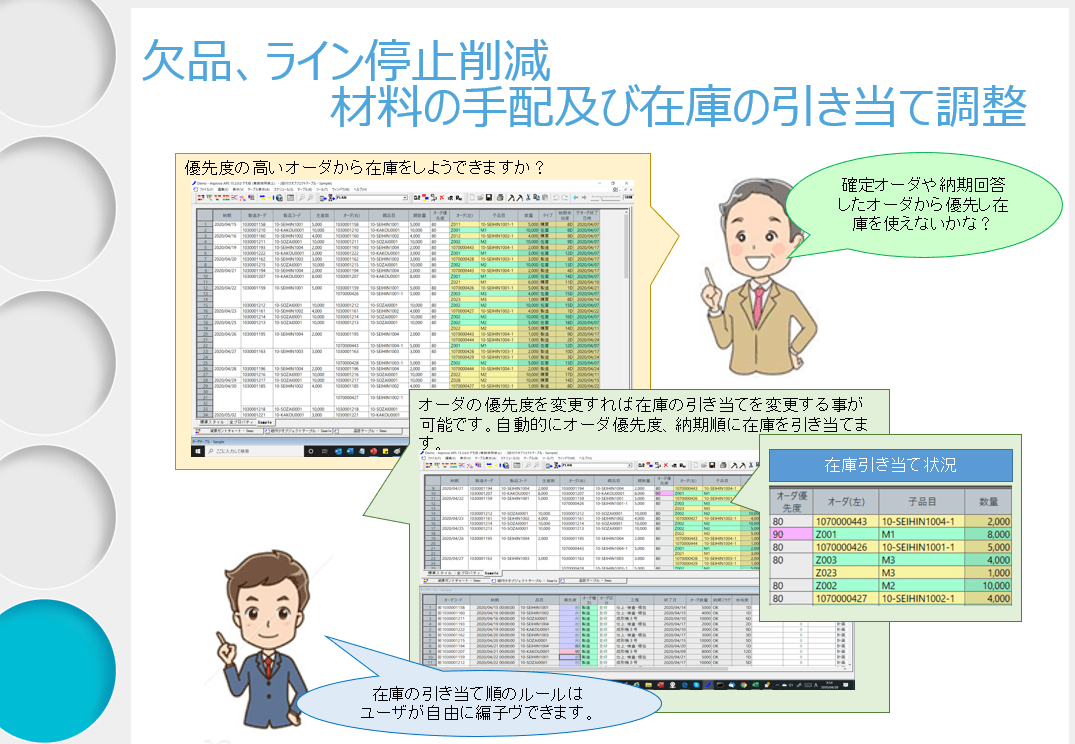

Reducing Shortages, Line Stoppages, Material Arrangements, and Inventory Allocation Adjustments

So far, we’ve discussed production. The earlier case study noted, "During the COVID-19 crisis, information sharing and collaboration are key," and "Objective metrics are needed to judge which tasks are affected and require immediate action." However, if materials run short due to demand fluctuations, production cannot proceed even when kanban circulates.

When delivery dates change due to demand fluctuations, material inventory allocation must also adjust. Using inventory for urgent items affects other tasks, requiring timely judgment on which tasks are impacted and whether issues arise.

Additionally, reflecting factory-specific rules, such as not reallocating materials for key customer orders to urgent items, becomes necessary.

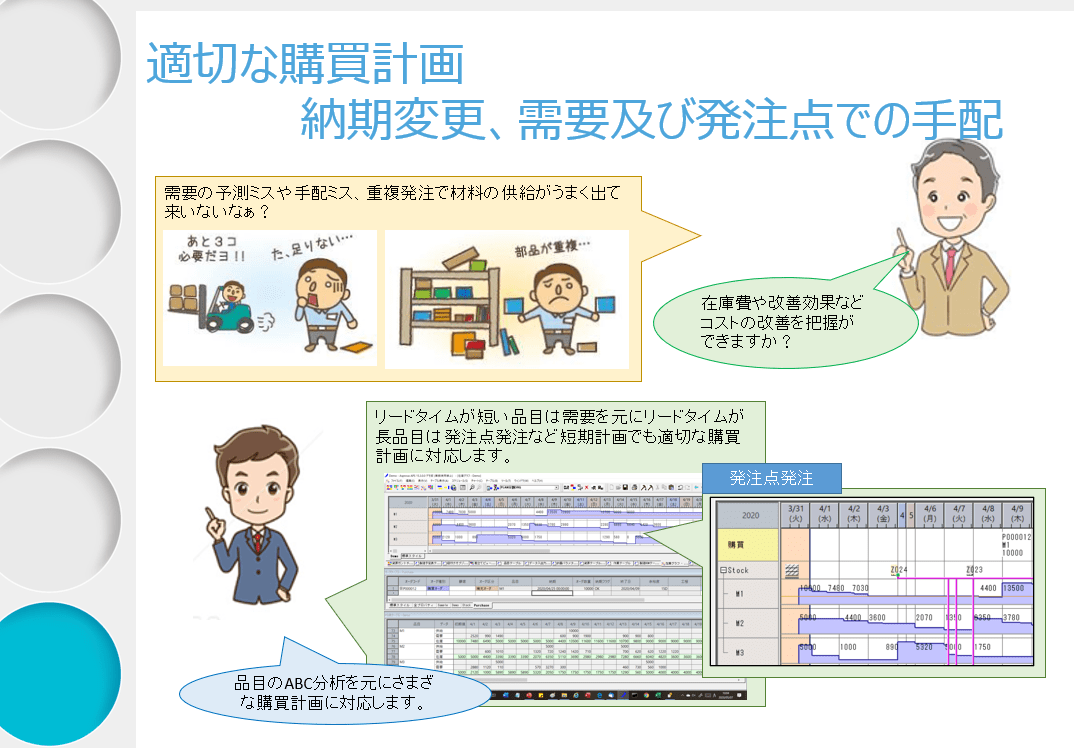

Appropriate Purchasing Plans, Delivery Changes, and Procurement at Demand and Reorder Points

Material allocation involves various conditions, another aspect difficult to manage with kanban alone. Even with production management MRP’s fixed lead-time stacking plans, allocating materials to actual production timing is challenging, necessitating a scheduler.

With demand fluctuations, not only material allocation but also purchasing changes daily. How does a scheduler address purchasing shortages or surpluses and differences in ordering methods by lead time?

For purchasing shortages, MRP automatically generates purchase orders, enabling judgment on which items to order and when. For over-purchasing, displaying end-of-period inventory data on purchase orders allows quantity adjustments, and outputting an over-purchasing list is possible. Releasing flags on ordered purchases allows Asprova to recalculate and resolve over-purchasing.

For items with short purchasing lead times, the scheduler runs MRP based on demand to create a purchasing plan. For materials with long lead times requiring some warehouse stock, the scheduler creates a reorder-point purchasing plan, triggering orders when inventory falls below the MIN level.