Load factor is the ratio of demand to a machine's supply capacity. In press processing, it is the ratio of the number of strokes required to fulfill an order to the strokes per hour (GSPH). On the other hand, operating rate is the ratio of actual operating time to available operating time, or the ratio of operating time needed to fulfill an order to the total daily available operating time. Production Control System in Indonesia It’s not limited to Indonesia, but it’s often said that the ultimate goals of the manufacturing industry are twofold: "cost reduction through productivity improvement" and "delivering products on time without delays." From a management perspective, business plans are crafted to maximize growth based on market supply and demand adjustments. However, even if sales increase due to low pricing, it only reduces gross profit, leading to losses from selling and administrative expenses or non-operating costs. On the other hand, raising unit prices isn’t straightforward due to market price considerations. Therefore, process management based on production plans aimed at reducing costs through ... 続きを見る

Takt Time and Cycle Time in the Toyota Production System

Takt Time (T/T) is a target value instructed by Toyota, the "boss," to its subcontractor "underlings," indicating how many seconds per unit they should process to properly fulfill Toyota’s orders.

For example, if Toyota places an order for 1,000 units per day with a subcontractor whose operating time is 15 hours per day (including 3 hours of downtime), the subcontractor would aim for a takt time of 43.2 seconds per unit, calculated as follows:

- (12 hours × 60 minutes × 60 seconds) ÷ 1,000 units/day

= 43,200 seconds / 1,000 units

= 43.2 seconds/unit

Cycle Time (C/T) is the standard operating time for one processing cycle. If the subcontractor processes at 40 seconds per unit, it results in excess capacity and overstock, requiring a reduction in operating time to adjust the pace. If it processes at 48 seconds per unit, it leads to insufficient capacity and shortages, necessitating efforts to reduce machine downtime through single-minute setup (setup within 10 minutes).

- If Cycle Time > Takt Time: Insufficient capacity (shortages)

- If Cycle Time < Takt Time: Excess capacity (inventory)

While takt time reflects a customer-centric (Toyota) perspective of how many seconds per unit are needed to meet order quantities, cycle time is a company-centric (subcontractor) metric based on the standard capacity of its production equipment.

In the Toyota Production System (TPS), the focus is on eliminating waste, overburden, and inconsistency (muri, muda, mura) to align cycle time (subcontractor’s capacity) with takt time (the capacity needed to fulfill Toyota’s orders).

Incidentally, takt time is straightforward as it is dictated top-down, whereas cycle time is calculated by the subcontractor’s production management department based on the planned operating time and target production volume for the upcoming year.

- Takt Time = Available Operating Time ÷ Daily Order Quantity

- Cycle Time = Target Operating Time ÷ Target Production Volume

Whether operating time includes setup time varies by factory, but TPS encourages subcontractors to adopt single-minute setup to achieve "Cycle Time = Takt Time."

Both takt time and cycle time are calculated by determining the time required based on production volume ("how many seconds to make one unit"). For example, if cycle time is 40 seconds per unit and the order is 1,000 units, the operating rate is calculated as follows:

- Operating Rate = Operating Time ÷ Available Time

= (40 seconds × 1,000 units) ÷ 43,200 seconds

= 92.6%

Load Factor in Press Processing Based on Stroke Count

While operating rate is calculated based on time using takt time or cycle time, for press-processed items, load factor is calculated from a machine-centric perspective. Instead of focusing on how many hours to operate, it considers GSPH (Gross Strokes Per Hour), the machine’s capacity including setup and downtime, and determines how many strokes are needed to fulfill the order quantity.

- Load Factor = Demand ÷ Supply Capacity

= Daily Stroke Count ÷ (GSPH × Operating Time)

Load factor is "the ratio of demand to a machine’s supply capacity," similar to operating rate in meaning. However, it avoids converting to units (how many can be produced) or time (how many hours to operate). It assesses whether the stroke count needed to meet demand (order quantity) fits within the supply capacity (how many strokes can be performed). If not, it calculates how many additional strokes to add as overtime, and if overtime isn’t enough, how many strokes to schedule on weekends—a stroke-based approach.

Load Factor Calculation for Right-Left Set Products Common in Indonesian Four-Wheel Parts Factories

In press or molding processes, producing multiple identical items in one shot is called multi-cavity production, while producing a right-left set in one shot is known as a right-left set product or co-produced item (tomodori). In Indonesia, these are called RL (Right-Left or Kanan-Kiri) products.

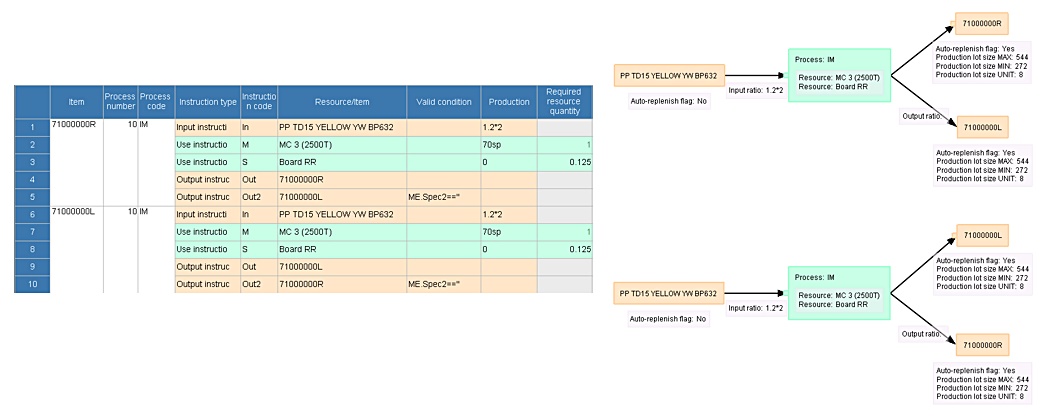

From a requirement planning perspective, when setting a 2-unit product in the BOM (Bill of Materials) of a production management system, it’s configured so that for one post-split parent item, 0.5 pre-split child items are needed—or equivalently, one child item is needed for two parent items.

For car door parts, a typical right-left set product, unlike standard 2-unit products, the parent item codes differ after splitting into right and left, and customers order them separately. Thus, separate BOMs are set for each right and left item code.

Assuming the site can produce according to the required quantities of right and left items, the MRP (Material Requirements Planning) function in the production management system correctly outputs manufacturing instruction quantities. However, load factor calculations inevitably deviate.

- Order for 100 right units only: Process 100 right units (100 shots)

- Order for 100 left units only: Process 100 left units (100 shots)

- Order for 100 right and 100 left units: Process both 100 right and 100 left (100 shots)

- Order for 60 right and 100 left units: Process both 60 right and 60 left (60 shots), then 40 left only (40 shots)

The production management system recognizes a total load of 200 shots for manufacturing instructions of 100 right and 100 left units (200 units total). However, the actual site completes the order of 200 units (100 right and 100 left) with just 100 shots.

Differences in Load Factor Calculation Between Production Management Systems and Production Schedulers

For 2-unit products, both the production management system’s BOM and the production scheduler’s BOM correctly calculate load factor by setting the child requirement as 0.5 for a parent requirement of 1, or 1 child for 2 parents.

In a production management system, the master data separates requirement planning (quantities) and load calculation: BOM sets parent-child requirements for requirement planning, standard load (cycle time) is set in the item-line master for load calculation, and the line’s standard capacity (daily capacity) is set in the line master.

This stems from the production management system’s MRP approach, which uses the line master’s standard capacity as a reference but stacks load with infinite capacity without considering order quantities, assuming manual adjustments to level out overloads, prioritizing requirement planning.

In contrast, a production scheduler integrates BOM, process information, and capacity (cycle time) into a single view, treating requirement planning and load calculation as inseparable by displaying capacity settings in the BOM or item-process master.

By setting the right BOM as the default output instruction and the left as an optional output instruction, unless specified at ordering, the system automatically produces an equal number of left units alongside the right manufacturing instruction, increasing inventory.

This aligns with the production scheduler’s core principle of deploying requirements based on order quantities without exceeding 100% resource capacity, based on cycle time.