Features of the handy terminal

Inventory management using barcodes, which is a common practice in Japanese warehouses, is still being considered by many Japanese companies in Indonesia.

There are three options for barcode reading devices: a scanner that pairs with a PC via cable or Bluetooth, a handy terminal that transfers data in batches, or a wireless handy terminal with an OS such as Windows CE.

The following is a rough list of the criteria needed to determine which one to choose.

- Scanner

- Inexpensive and easy to install, but it is positioned as an alternative to keyboard input

- Assuming you are working near a PC.

- The purpose is to obtain key information easily and accurately, and other necessary information is obtained by the PC side application.

- Handy terminal

- It is inexpensive, but it is necessary to develop programs with original development tools for handy terminals like Basic and VBScript.

- Designed for use in large warehouses and on site.

- Basic communication with the PC side application as a CSV file

- WIFI handy terminal

- It is expensive, but you can develop applications for the terminal with the feeling of normal PC development.

- Wireless LAN is a prerequisite for on-site use.

- Can be written directly to the server's database

In many cases, a batch-type handy terminal is selected by the method of elimination, "A scanner connected to a PC cannot do free work in the field, but a wireless handy is too expensive." However, it is necessary to develop two applications, one is a menu-style application for storing and taking inventory on the handy terminal side, and the other is an application on the PC side that connects data to the mission-critical system.

How to record results in the ERP system

In the case of using a batch-type handy terminal, there are two ways to use the results based on the instructions issued by the mission-critical system, in which the results are acquired based on the instructions issued by the mission-critical system, and the results are linked to the mission-critical system after checking whether the actual product is scanned according to the instructions, or the results acquired by scanning the actual product without any instructions are recorded in the mission-critical system.

- Actual results are recorded against instructions and reflected in the mission-critical system.

- Receiving: From the uninspected area to the material warehouse

Attaching the actual product label upon passing the inspection. - Material issue (GI order): from material warehouse to production site

- Material return:from the production site to the material warehouse

- Finished goods received:from the production site to the product warehouse

Attaching the actual product label upon passing the inspection. - Shipping (Picking List): from the product warehouse to the shipping area

- Disposal: from the warehouse to the disposal area

- Scaffolding (scaffolding tables): Warehouse

- Receiving: From the uninspected area to the material warehouse

- Reflecting un-directed performance in the mission-critical system

- Shelf movement: moving from shelf to shelf

Application development on the handy terminal side

On the handy terminal side, using the original script (Basic or VBScript-like language) provided by the manufacturer, we develop an application to perform warehouse entry/exit work with three basic functions: menu, button, and text box. However, the database that stores the instruction information and master data on the mission-critical system side in the handy side is free and lightweight (the core is only 225KB), all the basic SQL statements can be used, and the compatibility with CSV files is excellent.

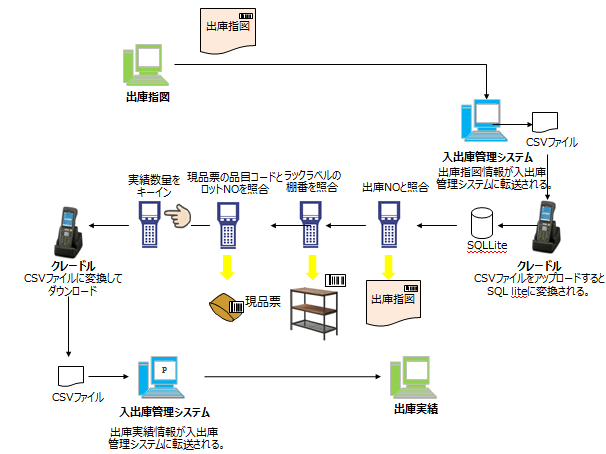

The left figure shows the flow of using Handy to correctly dispatch materials from the material warehouse to the manufacturing site based on the input schedule information described in the manufacturing instructions. The instruction NO printed on the header of the instructions issued by the mission-critical system is scanned, and a check is performed to see if the items of the corresponding lot are being dispatched from the shelf with the corresponding warehouse, and an error or an alert is displayed with an acceptable range for the difference from the actual quantity.

Using a CSV file with Handy Terminal means that the following four data conversions will occur.

- Convert DB to CSV file on the receiving/issuing management system side and upload it to Handy

- Importing CSV files into SQLLite on the handy

- Convert and download a CSV file from SQLLite on a handy

- Import into the DB of the warehouse management system

The barcode scanning of rack labels on shelves is done when the original shelf number is first read in the case of an outgoing process such as material release or shipment, and when the incoming process such as product receipt or product receipt is done at the end of the process, the destination shelf number is read.