Vouchers for shipping requests for all disbursements

When a customer in the manufacturing industry once asked us to install only an inventory management system, we decided to make it possible to issue slips by inputting delivery requests from the system, since there is not much difference between the current Excel management system and the receiving/issuing function alone.

In Indonesia, iron sheets and bars are easy to resell, and if manufacturing staff can freely take materials out of the warehouse, the risk of theft increases.

Since warehouse staff are not present during the night shift, production staff are required to submit delivery request slips in the evening and take out the materials used for the night shift, which prevents production staff from taking materials without permission.

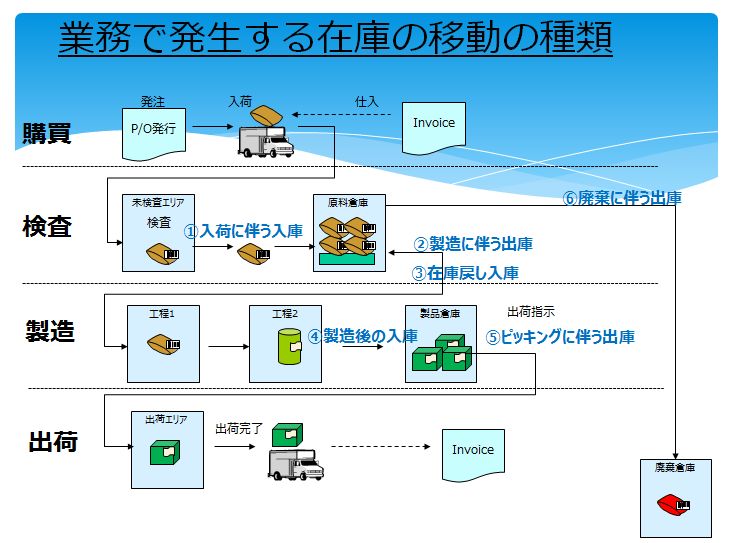

Furthermore, by registering the reason for delivery requests in the system, we can make the system versatile enough to be used in a wide range of applications, such as manufacturing delivery/outgoing instructions, subcontract delivery/outgoing instructions, shipping instructions, inter-warehouse transfer instructions, and disposal instructions.

Picking list for sorting into shipping areas

Usually, things to be shipped on that day are taken out of the warehouse in batches and stacked in the shipping area, so instead of working on a delivery request slip, it would be useful to have a list of daily work units.

In this case, the picking list is a list where shipping instructions linked to order information are entered in the shipping function of sales management, and the details of shipping instructions are bundled in units of days of sorting, apart from the shipping request slips of inventory management.

In the detail line of Picking List for shipment, the information of the incomplete part of shipment is described in the detail information of the issued shipping instruction list, and the key information is as follows.

- Shipping Instruction NO

- Item Code

- Lot NO

- Picking NO

The status of shipping instruction information includes a mixture of incomplete, partially shipped and shipped, and the picking list NO is needed to re-bundle information with the picking list NO, which means that the picking list NO is needed for the shipping instruction information.

If the item lot information on a physical item label is barcoded, the picking list can be imported into the handy terminal in advance and the item lot can be checked by simply scanning the barcode on the physical item label, making the sorting process more accurate.

When developing a delivery system using a handheld terminal, you need to be aware that the picking list is only used to ensure that the sorting process is accurate, and that shipments to the system are recorded in units of shipping instructions.