The purpose of the Beer Game is to recognize the importance of reducing inventory costs and opportunity loss costs (backorders) when making decisions about ordering and issuing manufacturing instructions within a supply chain that has a purchasing lead time of 4 weeks and a manufacturing lead time of 4 weeks. Production Control System in Indonesia It’s not limited to Indonesia, but it’s often said that the ultimate goals of the manufacturing industry are twofold: "cost reduction through productivity improvement" and "delivering products on time without delays." From a management perspective, business plans are crafted to maximize growth based on market supply and demand adjustments. However, even if sales increase due to low pricing, it only reduces gross profit, leading to losses from selling and administrative expenses or non-operating costs. On the other hand, raising unit prices isn’t straightforward due to market price considerations. Therefore, process management based on production plans aimed at reducing costs through ... 続きを見る

Overview of the Beer Game

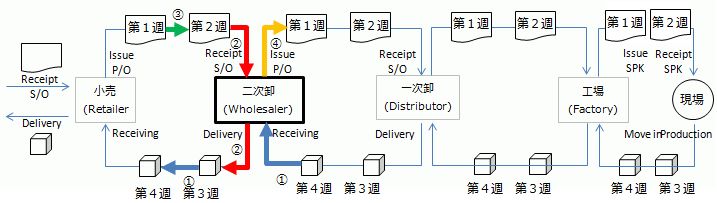

The factory operates on a make-to-stock basis, but in case of a stockout, it takes 4 weeks of manufacturing lead time from issuing a manufacturing instruction to product receipt. Wholesalers (retailers) ship from inventory, but in case of a stockout, it takes 4 weeks of purchasing lead time from placing an order with the factory (wholesaler) to receiving the goods.

In other words, if there is zero inventory in the supply chain, a purchase order (PO) issued by the retailer takes 16 weeks to arrive as a finished product.

Despite the Beer Game’s supply chain being a very simple assumption of one item per delivery destination, inventory fluctuations become significant if demand visibility is lacking between locations.

In reality, where it’s common to procure multiple items from multiple suppliers, the game highlights the difficulty of manual management by human systems.

The purpose of a production scheduler is to optimize the entire production site, whereas the purpose of a supply chain management (SCM) system is to optimize the entire supply chain.

Operations Occurring Within the Supply Chain

Within the flow of information and goods in the supply chain, the process involves receiving orders ⇒ placing orders (issuing manufacturing instructions) ⇒ receiving goods ⇒ shipping. Decision-making latitude exists only at the point of placing orders (issuing manufacturing instructions).

In other words, when considering optimization at one’s own site, the key is "how many to order (or produce)," which is why purchasing plans (production plans) are critical.

- Sales Operations

Move: Move the order form issued by the customer last week to the Week 2 start slot.

Review: Receive the order form from the customer.

Ship: Ship to the customer.

Move: Move last week’s unarrived shipped items to the customer to the Week 4 start slot. - Purchasing Operations

Order: Issue a purchase order to the supplier (decision-making latitude exists).

Receive: Receive goods from the supplier. - Manufacturing Operations

Move: Move the manufacturing instruction issued by the factory last week to the Week 2 start slot.

Review: Receive the manufacturing instruction from the factory.

Ship: Ship to the factory.

Move: Move last week’s unarrived shipped items to the factory to the Week 4 start slot.

Issue Manufacturing Instruction: Issue a manufacturing instruction to the site (decision-making latitude exists).

Receive: Receive goods from the site.

Thus, in operating the Beer Game, the tasks assigned differ by role.

- Factory: Sales operations and manufacturing operations

- Primary Wholesaler: Purchasing operations and sales operations

- Secondary Wholesaler: Sales operations and purchasing operations

- Retailer: Purchasing operations

Secondary Wholesaler’s Operations

For the secondary wholesaler, the above ordering and receiving tasks are performed in the following steps:

- Receive goods from the primary wholesaler

- Move unarrived items to the retailer to the Week 4 start slot

- Receive the order form from the retailer

- Ship to the retailer

- Move the order form from the retailer to the Week 2 start slot

- Issue a purchase order to the primary wholesaler

Retailer’s Operations

As the downstream end, the retailer has no customers further downstream, making it the role with the least tasks in the game.

- Receive goods from the secondary wholesaler

- Receive order cards from consumers

- Sell to consumers

- Issue a purchase order to the secondary wholesaler

Factory’s Operations

As the upstream end, the factory has no suppliers further upstream, making it the role with the most tasks in the game.

- Receive products from the site

- Move products from the site to the Week 4 start slot

- Move unarrived items to the primary wholesaler to the Week 2 start slot

- Receive the order form from the primary wholesaler

- Ship to the primary wholesaler

- The site receives manufacturing instructions from the factory

- The site ships to the factory

- Move the order form from the primary wholesaler to the Week 2 start slot

- Issue a manufacturing instruction to the site

Purchasing Plan and Production Plan

The only points with decision-making latitude are when issuing purchase orders and manufacturing instructions, where a plan must be made for "how many to order (or produce) this week."

- If Purchasing L/T (Manufacturing L/T) is 1 week = This week’s order (manufacturing instruction) arrives next week

- Outstanding orders (issued manufacturing instructions) also arrive next week

Under these conditions, if the forecast order quantity for next week is accurate, determining this week’s order quantity to balance the following equation would theoretically result in zero inventory costs:

- (Next week’s forecast order quantity + backorders) = (This week’s order quantity + inventory quantity + outstanding orders)

However, in reality, this doesn’t work due to the following reasons:

- Forecast order quantities are inaccurate

- Outstanding orders include "in-transit + shortage quantities," where shortage quantity = "ordered quantity – received quantity – in-transit"

- The arrival time of shortage quantities can only be predicted up to 4 weeks ahead

So, if I were to consider optimizing my own site, the following ideas come to mind, but they’re probably impossible within the short time limit during the game…

- Accurately predict next week’s order quantity based on market conditions

- If next week’s and the following week’s incoming quantities are low, increase order quantities to shorten the opportunity loss period

- If next week’s and the following week’s incoming quantities are high, reduce order quantities to shorten the inventory period

Reflections After the Beer Game

First, I was confused about starting with receiving goods. Oh, "In-Transit Week 2" means it’s assumed a PO (purchase order) was issued 4 weeks ago…

Once a PO is issued, it’s scheduled to be received in as little as 4 weeks. However, if a stockout occurs at the wholesaler due to delayed receipt from the factory, the issued PO accumulates as backorders at the wholesaler.

Human nature tempts us to issue extra POs to recover backorders, but theoretically, only the cumulative order quantity is shipped. Ordering extra may reduce backorders faster but increases inventory.

So, when backorders occur, a better strategy might have been to order extra upfront and reduce order quantities in subsequent weeks.

For the factory, if the customer operates on Saturdays while the factory rests on weekends, leveling production by dividing Saturday’s manufacturing quantity across 5 working days based on forecast data prevents delivery delays (backorders).

The reason for leveling is the factory’s finite capacity, but since capacity is infinite in this game, if backorders occur at the factory:

- Backorders + forecast order quantities for subsequent weeks

Issuing manufacturing instructions for this amount and adjusting production once backorder resolution is predictable might be better.

I still don’t fully grasp the significance of observing the upstream of the upstream (factory), but the textbook likely says it’s "necessary for overall optimization." Before that, I can’t even optimize my own site…

The bullwhip effect, where rumors amplify as they spread, largely depends on the personality of the site managers. Perhaps a panicky retailer at the downstream end could have amplified the bullwhip effect even more?