The reason why package systems are developed with assembly-type manufacturing processes in mind is that standardizing operations is easier. In process-type manufacturing, a continuous line is used, meaning that tasks in the current process and the next process are performed consecutively without any idle time, and there is no chance for tasks from other orders to interrupt. Production Scheduler in Indonesia In Indonesia's Japanese manufacturing industry, the adoption of production management systems has been increasing. However, when it comes to one of the key challenges in production management—creating feasible production plans that take machine and equipment loads into account—manual work using Excel remains the standard practice. As a result, the demand for production schedulers is expected to grow in the future. 続きを見る

Assembly-Type and Process-Type Manufacturing Processes

When introducing a production management package system, the basic premise is to align the customer’s operations with the package’s standard workflow. However, many package systems are developed for assembly-type manufacturing processes because standardizing operations is easier in assembly-type processes compared to process-type ones. In process-type manufacturing, where standardizing operations is more challenging, some form of customization is often applied.

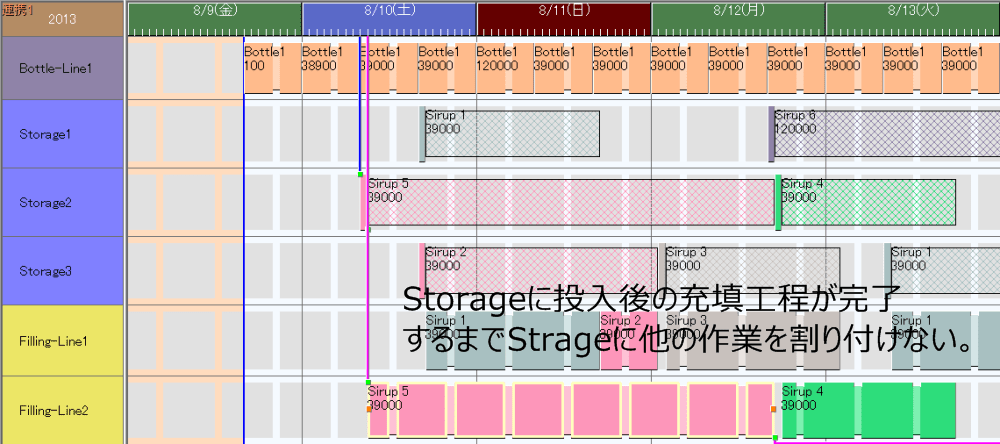

In process-type manufacturing processes, a continuous line is used, so tasks in the current process and the next process are performed consecutively without idle time, and there is no chance for tasks from other orders to interrupt. Additionally, process-type manufacturing often involves the use of tanks. Once the preparation tasks in the current process are completed in the tank and the contents are transferred to the next process, no tasks occur in the current process while waiting for the transfer to finish. During this period, there is a constraint that prevents assigning other orders to the tank until the contents have fully flowed out.

- How much time to allow between the current process and the next process

- After completing tasks in the current process, the next process must start within 1 hour to prevent fermentation or quality degradation.

- No other orders are assigned between the current process and the next process (no idle time is created between processes).

- After completing tasks in the current process, do not assign other orders for a certain period

- The tank remains occupied for 3 hours after the tasks are completed.

- The tank remains occupied for 60 minutes after the next process starts.

- The tank remains occupied until the next process is completed.

- Do not allow tasks to span across days

Do Not Assign Tasks from Other Orders Between the Current Process and the Next Process

The production scheduler Asprova creates a production plan that maximizes operating rates by assigning tasks from other orders to idle times in the line. However, it can also create a plan that prevents tasks from other orders from interrupting the consecutive operations in a continuous line.

- Turn on the "Enable Overlap MAX" setting in the planning configuration.

- Set the overlap method in the manufacturing BOM to "ES (End Start)."

- Set the "Overlap MAX" in the manufacturing BOM to 0.

Do Not Assign Other Orders for a Certain Period After Completing Tasks in the Current Process

It is possible to create a production plan that locks out tasks from other orders until the start of the next process or the completion of the next process after the current process tasks are finished.

- Turn on the "Resource Lock" setting in the planning configuration.

- Set the resource lock in the resource table to "PE (Parent End – until the next process ends)."

Do Not Allow Tasks to Span Across Days

When manufacturing involves a continuous line from liquid preparation to filling, it is necessary to create a production plan that prevents tasks from spanning across days and interrupting production time.

- For 24-hour operations, set the shift table to 0:00–23:59 with a 1-minute interruption.

- Set the "Maximum Manufacturing Interruption Time" in the resource table to -1M.