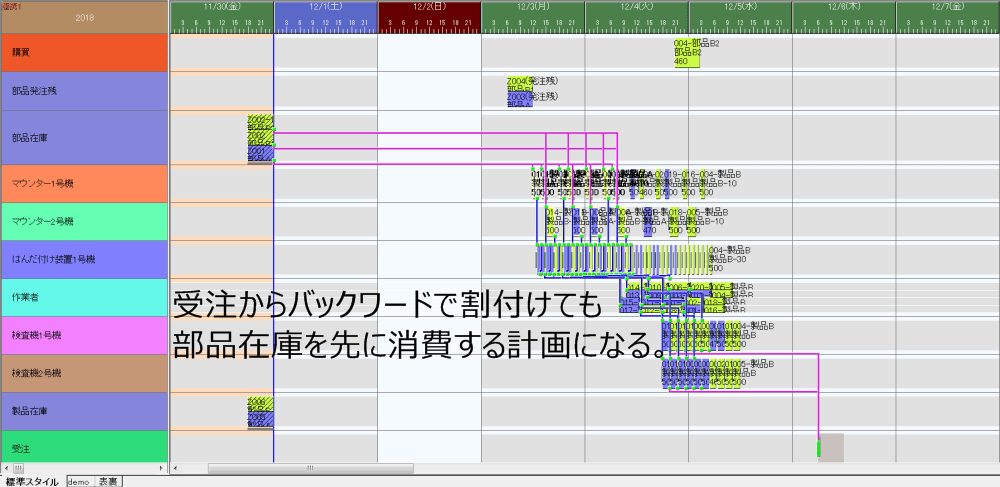

If assignments are made forward from the initial process using raw materials, a plan that naturally consumes inventory first can be created. However, if assignments are made backward from processes closer to shipping, manufacturing orders for work-in-progress are generated first, and inventory is allocated to the final shortfall, potentially preventing a plan that prioritizes inventory consumption. Production Scheduler in Indonesia In Indonesia's Japanese manufacturing industry, the adoption of production management systems has been increasing. However, when it comes to one of the key challenges in production management—creating feasible production plans that take machine and equipment loads into account—manual work using Excel remains the standard practice. As a result, the demand for production schedulers is expected to grow in the future. 続きを見る

Prioritizing Raw Material Inventory Consumption vs. Manufacturing to Meet Shipping

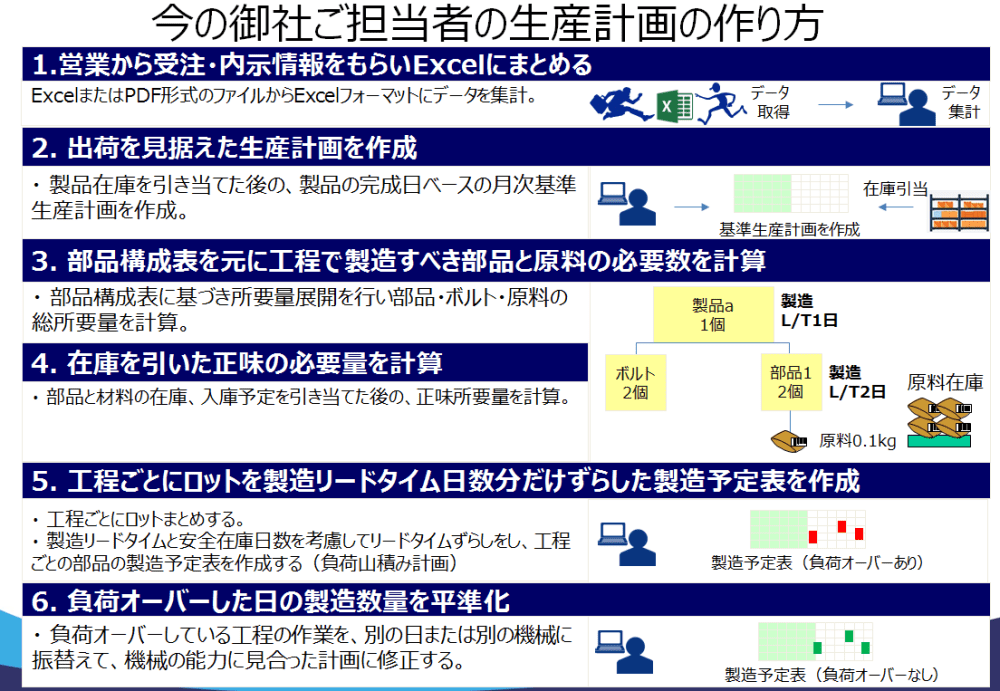

In Indonesian manufacturing, planners typically from the PPIC (Production Planning and Inventory Control) department create a production schedule (baseline production plan) based on forecasts or orders from the sales department, subtracting product inventory to determine completion dates. They then break down the bill of materials (BOM) to generate manufacturing orders for process-specific work-in-progress, shifting dates while accounting for safety stock days.

This results in manufacturing orders stacking up on the calendar. Planners then adjust overloaded days by moving orders forward or to other machines, crafting a production plan digestible by the factory’s equipment.

This method is called backward scheduling. Conversely, generating manufacturing orders sequentially from the initial to final processes based on required order quantities and assigning them to machines is called forward scheduling.

In practice, after confirming no delays with backward scheduling, planners often shift production forward to avoid excess inventory while boosting utilization rates, resulting in a hybrid of backward and forward scheduling.

Regardless of the planning method, from a first-in-first-out raw material inventory perspective, it’s natural to prioritize manufacturing with available raw material stock. Forward scheduling from the initial process using raw materials naturally creates a plan that consumes inventory first.

On the other hand, backward scheduling from processes closer to shipping generates manufacturing orders for work-in-progress to meet shipping needs first, allocating raw material inventory last, which may not prioritize inventory consumption.

Planning to Produce Orders with Available Raw Material Inventory First

To create a plan prioritizing production of orders with available raw material inventory, the production scheduler Asprova, during backward assignment, first assigns “replenishment orders for raw materials generated from received orders that are linked to purchase orders or open orders other than physical inventory.” This naturally assigns orders linked to physical inventory last, crafting a plan that prioritizes production with available material inventory.

To assign manufacturing orders linked to non-inventory raw material orders first in backward scheduling, set the following assignment rule (dispatching rule) in descending order:

- IF(SumIF(ME.Order.'Child Order (Recursive)',TARGET.Item.ItemType=='Raw Material'&&TARGET.OrderType!='Inventory (Absolute Quantity)',TARGET.OrderQuantity)>0,1,0)

When MRP (Material Requirements Planning) doesn’t account for raw material purchase orders or open orders, setting the earliest start date of manufacturing orders to the raw material availability date (e.g., delivery date) creates a plan considering raw material constraints. However, while this works in forward scheduling, it may not be effective in backward scheduling from later processes when equipment capacity has slack.

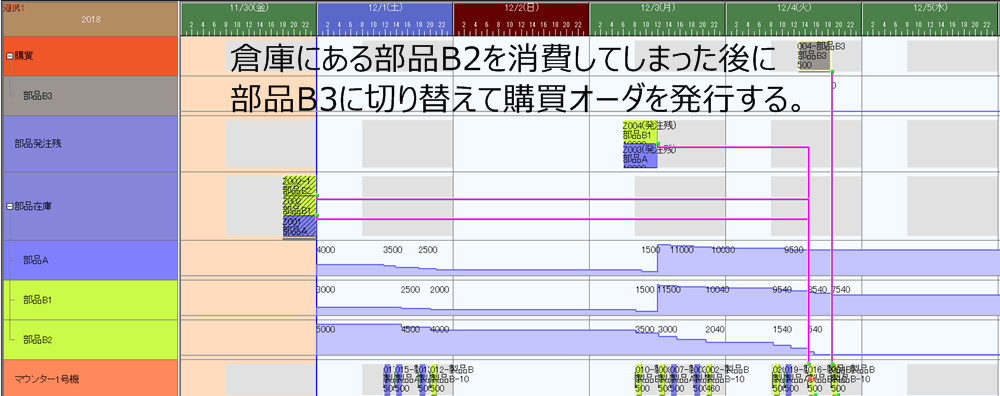

Switching to Alternative Raw Materials When Current Inventory Runs Out

For the initial board mounting process, a raw material constraint can be set to switch from part B2 (current warehouse inventory) to part B3 after B2 is depleted.

- Set the instruction code for parts B2 and B3 in the manufacturing BOM to In2 as alternative raw materials.

- Set auto-replenishment for part B2 to “No” in the item table.

- Set the raw material switch target for part B2 to part B3 in the item table.

- Set auto-replenishment for part B3 to “Yes (Inventory + 1-to-1 Production)” or “Yes” in the item table.

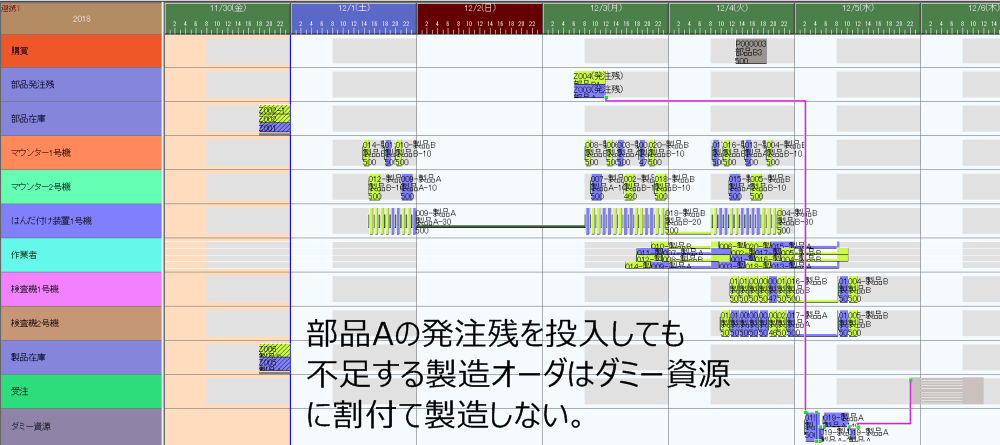

Avoiding Production of Manufacturing Orders Without Raw Material Inventory or Open Orders

A production plan can be created to avoid manufacturing orders that exceed available raw material inventory or confirmed open orders (received quantities).

- Set auto-replenishment for part A to “No” in the item table.

- Set the raw material constraint flag for part A to “Yes” in the item table.

- Set “Yes” to impose raw material constraints in the planning parameters.