Proposal of production scheduler operation method

In general, it is rare to done master maintenance or actual result input on the production scheduler, and normally maintenance of the master data to be used by the scheduler is done on the production control system side or the external DB, and the latest master data is imported at the time generating orders by production scheduler.

When you issue a production order with the production control system, the generated order is imported as a production order. Howeverif you only input the actual results in the production control system, we will collect actual results on the external interface system and import this as production result.

By processing the data accumulated on the production control system or the external DB side, it is possible to create a report on the load calculation and the forecast management, in order to convince Indonesian key person about the price and the validity of the introduction period , it is meaningful to extend the width of the function to the side to give a feeling of volume of service.

Input interface

Although it is possible to generate a Integrated Master by integrating the Bill of Material, machine capability, standard load and unit quantity in production control system, but it is rare cases that these pieces of information are complete.

When setting the machine capacity and the standard load of each item in production control system, the item and line at the time of pile creation calculation by MRP are a one-to-one relationship, and there is no meaning to set a load for an alternative line of a certain item

- Capacity of line in a day

⇒Machine Capacity(75,600 Sec/Day)or(9,450 Pcs/Day)or(16 Hour/Day) - Load per item by line

⇒Production quantity by standard load(8 Sec/1 Pcs)or(1 Sec/0.125 Pcs)or(2000 Pcs/1 Hour)

In other words, in both the production scheduler and the production control system, need to set the cycle time for each item, which is the ratio of machine capacity and standard load for each combination of item and line.

However, in the production control system, since the combination of item and line applied in MRP is limited to only one, maintenance of machine capacity tends to be negligible and there are only a few cases where the data of the production control system can be directly interfaced without any adjustment.

Therefore, only the item information is interfaced from the production control system, and the machine information is managed by the external DB.

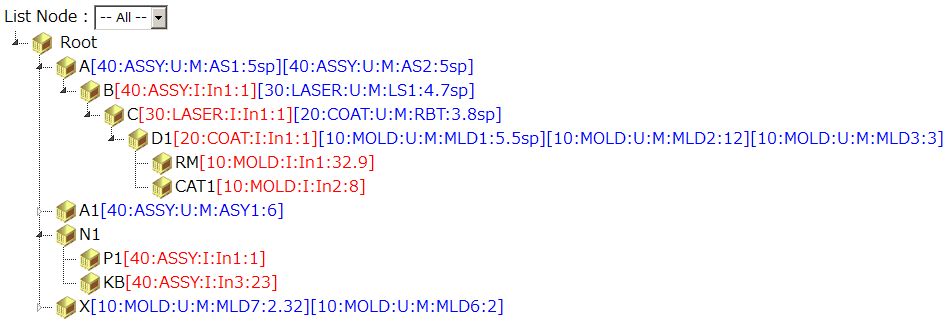

In the input interface, by merging the item information (input instruction) and resource information (use instruction) with the parent (item), child (item or resource), order type as the primary key, create integrated master of production scheduler.

The functions of the input interface are as follows.

- Function to generate Integrated Master from BOM of production control system and machine information of external DB.

- Additional master maintenance function such as machine information.

- Function to reference, add, modify, and delete items and resources from the tree view.

- Function to check looping

It is aimed at improving work efficiency by visualizing the tree maintenance view on a web basis based on division of the master maintenance work that takes time, making it visible, and putting it in mutual monitoring status.

Result collection interface

What is real time for?

When there is a demand to "see progress situation in real time at production scheduler", it is necessary to clarify real-time definition before that.

As an example of collecting actual results in real time, acquiring actual data counted by a sequencer and saved in a DB through an interface, scanning a barcode of an item tag with a barcode scanner and on and on.

On the other hand, it is an example of batch processing to input the daily work report into the system by 10 o'clock the next morning. but I am not sure whether it is batch or realtime to upload the results gathered by a batch scanner every hour for CSV .

In short, the difference between real-time and non-real-time is only the difference in the time interval from the timing when the processing is physically finished on the line to the timing when the actual result is reflected in the system.

If so, we should decide the best method after clarifying what we want to do by seeing "real-time progress".

How to reflect process progress control in inventory control

I think that the most simple way is to carry out process progress management on a production order basis at the production scheduler, and to reflect the results to inventory by importing the results into the production control system.

- Actual results are entered into the production management system and actual results are input to the production order (with progress management)

Generate production order with production scheduler ⇒ Import CSV from order detail list of production control system ⇒ Collect actual results in real time ⇒ Import manufacturing results into production scheduler - The actual results are entered into the production control system, but the actual results are entered per item (with progress management)

Generate production order at production scheduler ⇒ CSV import from production detail management order ⇒ Collect actual results in real time ⇒ Allocate actual of day, line and item units in order of production order ⇒ Import manufacturing results into production scheduler - The actual results are entered into the production control system, but the actual results are entered in item units (without progress management)

Generate production order at production scheduler ⇒ CSV import from production detail management order ⇒ Collect actual results in real time ⇒ Allocate actual of day, line and item units in order of production order ⇒ Import manufacturing results into production scheduler. - The actual results are input to the production scheduler and uploaded to the production control system (with progress management)

Production order generated by production scheduler ⇒ Collect actual results in real time ⇒ CSV import from Manufacturing result without plan of production control system.

Functions of result collection interface

Functions to be included in result collection interface are as follows.

- Input actual result to production order (with progress management).

- Allocate the results of the day, the line, and the item unit in the order of the production order (with progress management).

- Import results of day, line and item unit as inventory order (no progress management).

- Function to convert actual results into CSV and I / F to the production control system.

- Function to enter actual results with cable type bar code scanner

- A function to import a CSV file acquired from a batch type barcode scanner.

It is difficult to ask to input actual result on the production order at the manufacturing site where there is no culture to report actual result in the production order, so the result of the item unit is allocated to the production order by the system and the order. It will prevent you from getting bad impressions from taking the time to collect results from the beginning of operation.

Output interface

We will manage the batch using the actual item slip in order to record the production results on production order by the production scheduler and reflect the process progress management at the production scheduler in the inventory management of the production control system, It is necessary to have an output interface that can easily execute functions such as issuance.

Reissue of actual item label at lot division

In order to scan a barcode with a barcode scanner, it is necessary to output production order on which a barcode is printed, but the problem are processing when the lot (or palette) is divided.

In the case of lot integration, since the two production orders on the system move together in one place on the field, the system does not do anything and it can flow with 2 pieces of actual item label and input results separately. However, in the case of lot division, it is necessary to issue newly since the physical item label is required two pieces.

We will implement the method of issuing an item label of this divided lot as a derivative function of the reissue function of the existing lot. In other words, if you set the radio button "Normal / Divide" on the issue slip issued screen retrieved by lot number, and if division is selected, execute derivation process of reissue.

- Quantity is blank, lot number (branch numbering) ・ item ・ scheduled start date ・ line name is usually

- Quantity is blank, lot number ・ item ・ scheduled start date ・ line name is normal

- Lot number and quantity are blank, item ・ scheduled start date ・ line name is normal

- Issuing a complete empty slip and entering by handwriting

Actual quantity of divided lot is updated by time series on actual production quantity by production order or by actual quantity (addition). Because integration and division of lots are caused by situations in the field, it is impossible to divide and feed back the production order of the system every time it occurs, so we have the goal of process progress management and inventory management at the beginning of planning.

Replacement of actual item label when the lot of the previous process and the next process are different

Since the lot size is different between the molding or pressing process which is the previous process and ASSY or welding which is the next process, it is necessary to replace the actual item label and the function of the subsystem which can be issued at any time by item and lot is necessary. However, if you do not make it distinguish whether it is already issued or the first issue, the actual lot of the same lot will be inundated at the site.

Output Report Type

If you have the following as a management report to be packaged in the output interface, I think that it is enough in the sense that "Expanding the volume of service by expanding the width of the feature" at the time of pre-sales.

- Manufacturing Order or Actual Item Label(Operation)

- Daily Production Plan by Line(Operation)

- Monthly Production Plan by Item and Line(Information)

- Daily Production Comparison List(Inpormation)

- Occupancy Rate Comparison List by Line(Information)