Beer Game Overview

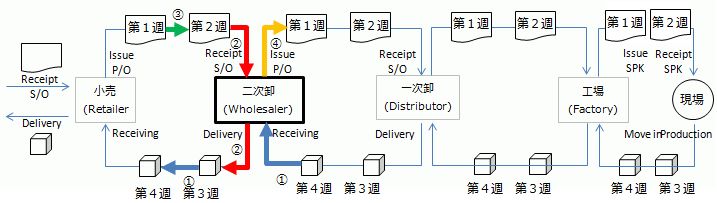

The factory is a prospective manufacturer (Make To Stock), but in the case of a shortage, it takes 4 weeks of manufacturing lead time from manufacturing orders to product delivery, and the wholesale (retail) ships from stock, but in the case of a shortage, it takes 4 weeks of purchasing lead time from ordering to receiving from the factory (wholesale).

So, if there is zero inventory in the supply chain, a PO issued at retail will take 16 weeks to arrive as a product.

In the beer game's supply chain, despite the very simple assumption of one item and one delivery location, inventory fluctuations can be severe if demand is not visible between locations.

And since it is normal to purchase multiple items from multiple suppliers in reality it is a game that poses the problem that manual management by human beings is difficult.

The goal of the production scheduler is to optimize the entire production base but the goal of the supply chain management system (SCM) is to optimize the entire supply chain.

Operations that occur in the supply chain

In the flow of information and goods moving through the supply chain, the process goes from order to order (manufacturing instructions) to receiving to shipping, and in this process, there is room for decision-making to take place only at the time of ordering (manufacturing instructions).

In other words, when you think about the optimization of your base, the number of orders you need to place (to manufacture) is the key to success, and this is the reason why the purchasing plan (production plan) is so important.

- sales operations

Move: Move the order form issued by the client in the previous week to the square where the week 2 begins.

View Order Form: Receiving Order Form from Customer

Shipping: Shipping to customers

Move the undelivered items that were shipped to the customer the week before to the starting square of week 4. - Purchasing

Place an order: issue a purchase order to your supplier (with room for decision)

Incoming goods: incoming from suppliers - Manufacturing

Move: Move the manufacturing instructions issued the week before from the factory to the square where week 2 begins.

Viewing Production Orders: Receiving Production Orders from the Factory

Shipping: Shipping to the factory

Transfer: undelivered items shipped the previous week to the factory are moved to the starting square of week 4.

Issue manufacturing instructions: issue manufacturing instructions to the field (with room for decision-making)

Incoming: incoming from the field

Therefore, the duties assigned to each role in the operation of the beer game are different.

- Factory: Sales and manufacturing operations

- Primary wholesaling: purchasing and sales operations

- Secondary wholesaling: sales and purchasing operations

- Retail: Purchasing

Secondary wholesale business

In the case of a secondary wholesaler, the above ordering process is carried out in the following manner.

- Inbound from primary wholesalers

- Move undeliverable items to retail stores to the start of week 4 mass

- Received order form from retailer.

- Shipment to retail stores

- Move the order form from the retail store to the square where week 2 begins.

- Issue purchase orders to primary wholesalers.

Retail Operations

The retail stores, which are downstream of the end of the line, have the least amount of work to do in running the game because they don't have any downstream specialties.

- Coming in from secondary wholesalers

- Receiving an order card from the consumer.

- Selling to Consumers

- Issue purchase orders to secondary wholesalers.

Factory operations

The factory, which is upstream of the end of the game, has no upstream suppliers, so the factory personnel have the most work to do in terms of game operations.

- Receiving products from the field.

- Move product from the field to the masses where week 4 begins

- Move undelivered items to primary wholesalers to the start of the second week

- Received order form from primary wholesaler.

- Shipping to primary wholesalers

- The site is receiving manufacturing orders from the factory.

- The site is shipped to the factory.

- Move purchase orders from primary wholesalers to the start of the second week

- Issuing manufacturing instructions to the field

Purchasing and Production Planning

The only time you have room for decision-making is when you issue a purchase order and manufacturing instructions, where you need to plan how many units you will order (manufacture) this week.

- One week for purchasing L/T (manufacturing L/T) = This week's orders (manufacturing orders issued) are received the following week

- Backlog of orders (manufacturing orders on file) will arrive the following week

Then, if the forecasted order quantity for the following week is correct, theoretically, if the order quantity for this week is balanced by the following, the inventory cost will be zero.

In reality, however, it does not work for the following reasons

- Projected order quantity will be missed.

- The order backlog is "In-transit + quantity of missing items" and the quantity of missing items is "Quantity ordered - Quantity in stock - In-transit".

- I can only read up to four weeks ahead of time when the missing quantity will arrive.

So if I were to think about optimizing my own base, I can think of the following, but probably not in the short time limit of the game in progress...

- Accurately forecast next week's order volume from market conditions

- If the next week and the week after that, increase the order quantity and shorten the opportunity loss period if the quantity received is low.

- If the quantity of goods in stock the following week or two is high, reduce the quantity ordered and shorten the inventory period.

Reflections after the beer game

I'm bothered by the fact that we're starting with incoming shipments first. Oh, the second week of In-Transit assumes that the P/O (purchase order) was issued 4 weeks ago...

When a P/O is issued, it is expected to be received in four weeks at the earliest. However, if there are any shortages at the wholesalers due to delays in the delivery of goods from the factory, the issued P/Os are accumulated at the wholesalers as a backlog of orders.

It is tempting to issue a larger quantity of P/Os to recover the backlog, but theoretically, we only ship the accumulated amount of orders, so placing an order for a larger quantity has the effect of reducing the backlog quickly, but at the same time it increases inventory.

Therefore, when an order backlog arises, it may have been a good idea to place a larger order ahead of time to reduce the amount of orders from the following week onward.

In the case of a factory, if the customer is open on Saturdays and the company is closed on Saturdays and Sundays, when the unofficial notice is spread out, the manufacturing volume for one Saturday is divided by five operating days to prevent delivery delays (backlog).

The reason for the leveling-off process is that the plant has a finite capacity, but in this case, because the capacity is infinite, if the plant has a backlog of orders, the plant will take the following measures

- Backlog + Forecasted orders from next week

It might be better to issue a production order for the first time and adjust production when the order backlog is predicted to be eliminated.

I still can't pinpoint the significance of looking at the upstream upstream (plant), but maybe the textbook says it's necessary to think about overall optimization, but I can't even optimize my own bases before that....

I also think the bullwhip effect, where rumors tail off and grow, depends largely on the nature of the people in charge of the bases. So maybe the end downstream process, the retail personnel, could have had a bigger bullwhip effect if they were an awkward person?