mcframe is an integrated package for production management, sales management, cost management, etc. It flexibly meets the diverse needs of the manufacturing industry and is a proven DX solution for core business operations used by many customers in Indonesia.

Production Management and Productivity IoT Solutions Now!

Non-personal, non-contact operations are becoming mainstream in the manufacturing industry in Indonesia after the Corona pandemic, and IoT technology is attracting attention for its ability to accurately and automatically obtain the operating status of manufacturing equipment from various devices, eliminating management using handwritten daily reports.

- Understand the condition of machine and evaluate it correctly

- Maintain optimal machine performance

- Obtain necessary information accurately and quickly

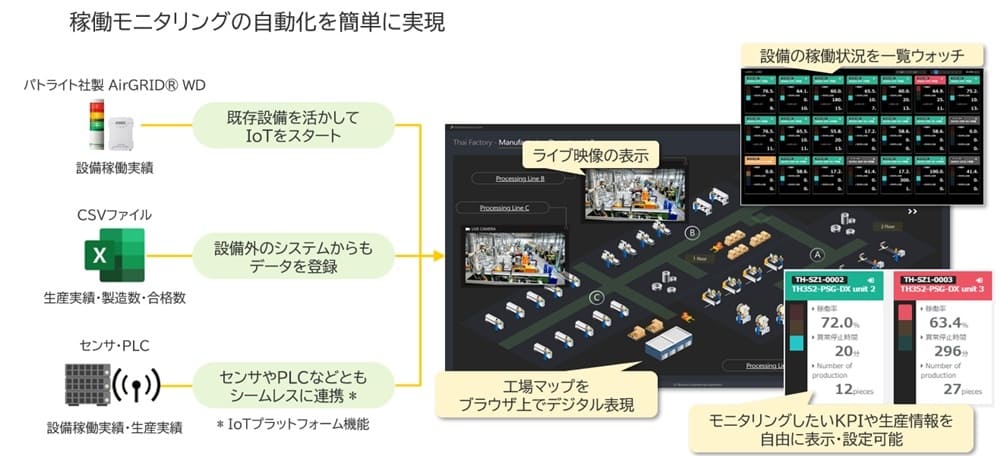

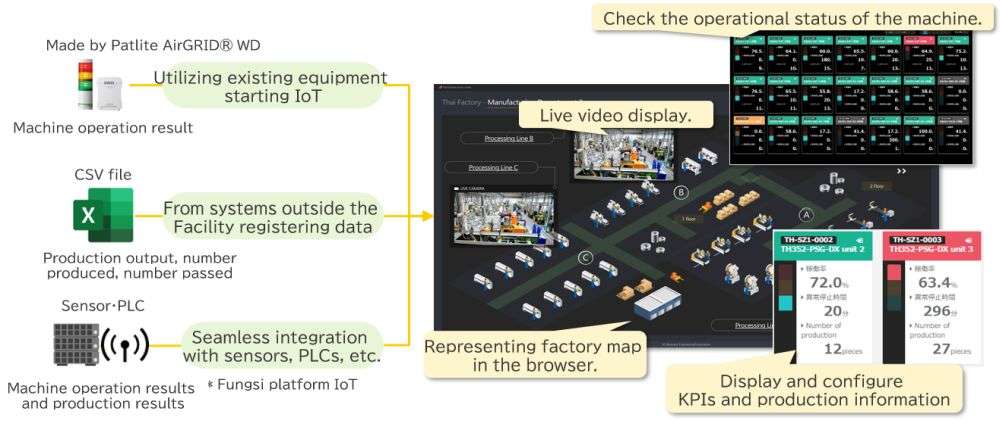

By converting paper forms, machine operation, and human work into data, business processes, machine, and human work can be connected in a short period of time.

mcframe Signal Chain for operations and machine maintenance management

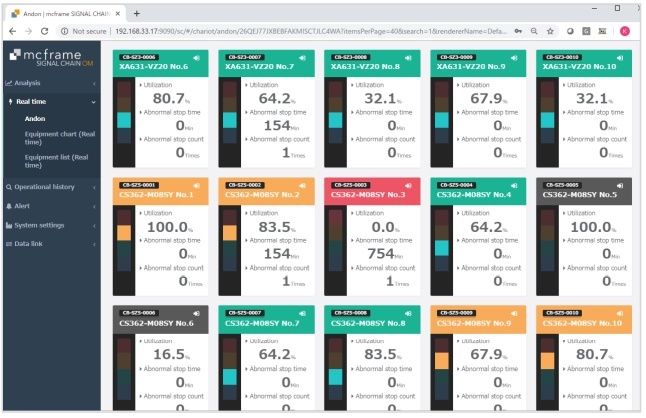

Acquire operating data from patlites (signal lights) and PLCs via wired and wireless connections, and monitor machine operating status on a PC or monitor in real time to check equipment operating history. It is also possible to grasp operating trends on a weekly and monthly basis.

In addition, daily changes and failure trends of machine are analyzed numerically, and equipment charts and trouble cases are shared among all departments to realize a new casual and powerful maintenance operation through IoT.

mcframe Signal Chain can remotely check machine operating status by plant and manufacturing department, analyze the situation based on the reason for the outage entered, and evaluate overall equipment efficiency (OEE) by obtaining performance and quality information from external sources.

-

-

Operational Management, Trend Management, and Predictive Maintenance through the Introduction of IoT in Manufacturing in Indonesia

In the context of IoT in manufacturing, "connecting things to the internet" refers to collecting data on the actual quantities and times of production goods like products, as well as maintenance information for capital goods such as machinery. However, conducting operational and trend management for predictive maintenance, and using that data to prevent machine downtime or analyze the causes of performance degradation, directly contributes to productivity improvements.

続きを見る

Please feel free to contact us to discuss how IoT can help you manage operations and facility maintenance management in Indonesia!