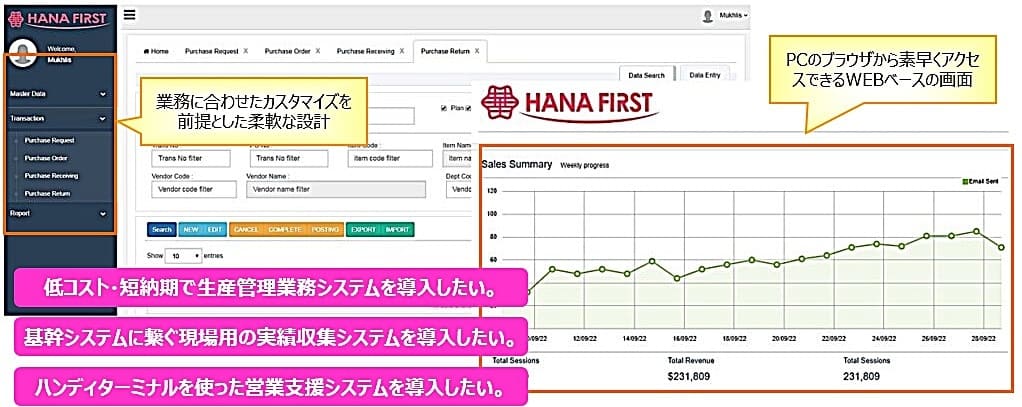

When systematizing business processes in Indonesia, it is important to replace them gradually with simple, low-maintenance functions. However, general packaged software products tend to have complex features to ensure versatility, making it impossible to extract and implement only the necessary functions from the product.

Do You Have Any Concerns About Improving Production Management Operations?

- Want to implement a sales, purchasing, inventory, and production management system at low cost and with short delivery times.

- Want to systematize purchasing and inventory management for consumables or spare parts.

- Want to introduce a performance collection system for on-site use that connects to the core system.

- Want to implement a sales support system using handheld terminals.

With the Hana First business system development template, you can progressively systematize operations by prioritizing high-priority functions while reflecting on-site needs.

Benefits of Systematizing Production Management and Performance Management with Hana First

By incorporating on-site requirements into the minimal basic functions compatible with any industry, which are pre-implemented in the Hana First development template, development and implementation periods can be shortened.

Additionally, since it operates on a web browser, there’s no need to install it on client PCs, and our company can provide rapid remote support directly to the server.

- Implementation in a short time at low cost

- Reflect on-site requirements into versatile basic functions, shortening implementation time and reducing labor costs.

- No installation required on client devices, enabling a system with rapid remote support.

- Low maintenance costs after implementation

Basic functions and user interfaces that arise within a series of business processes are implemented as templates.

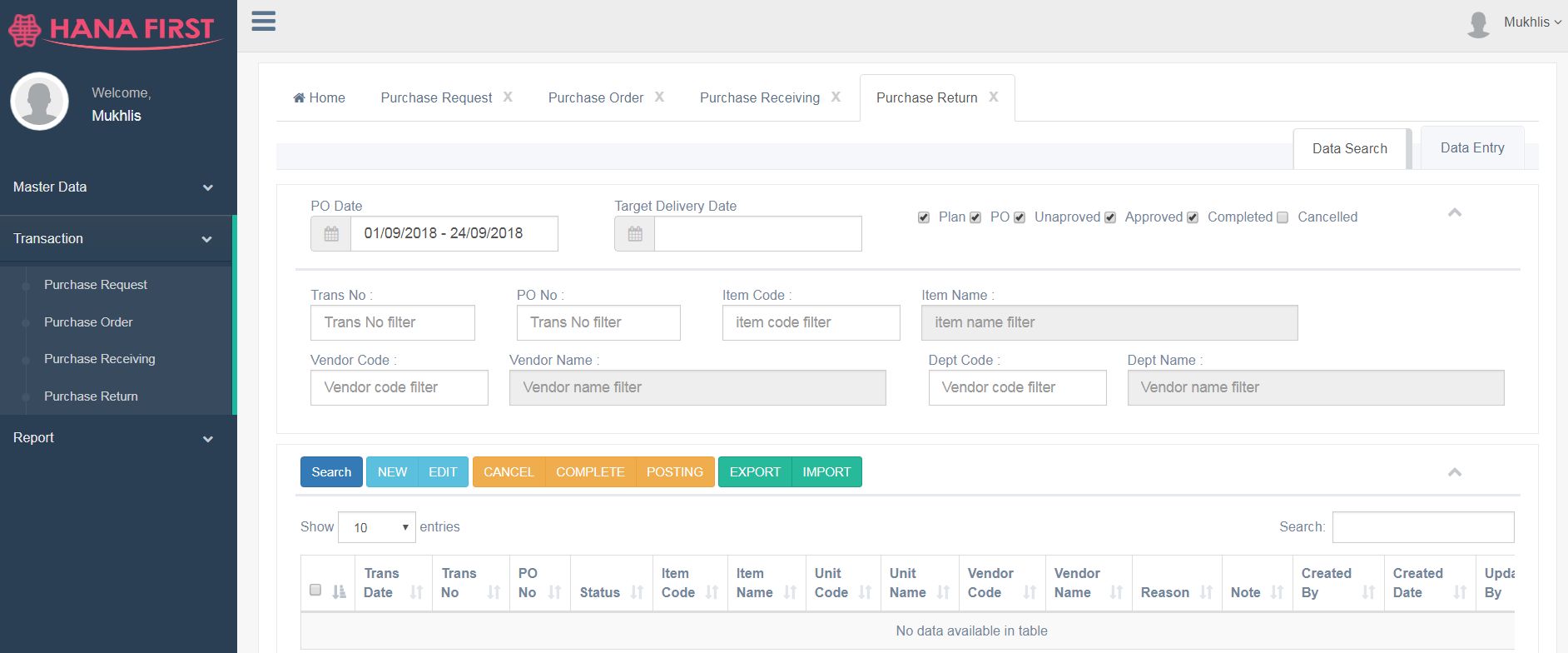

Purchase Management

Based on purchase requests entered by each department, order entries are made, purchase orders are issued, receipt records are logged, delivery slips are issued after receipt, and defective items discovered after receipt are registered as return receipts.

Purchase request / Purchase Order / Purchase Receiving / Purchase Return

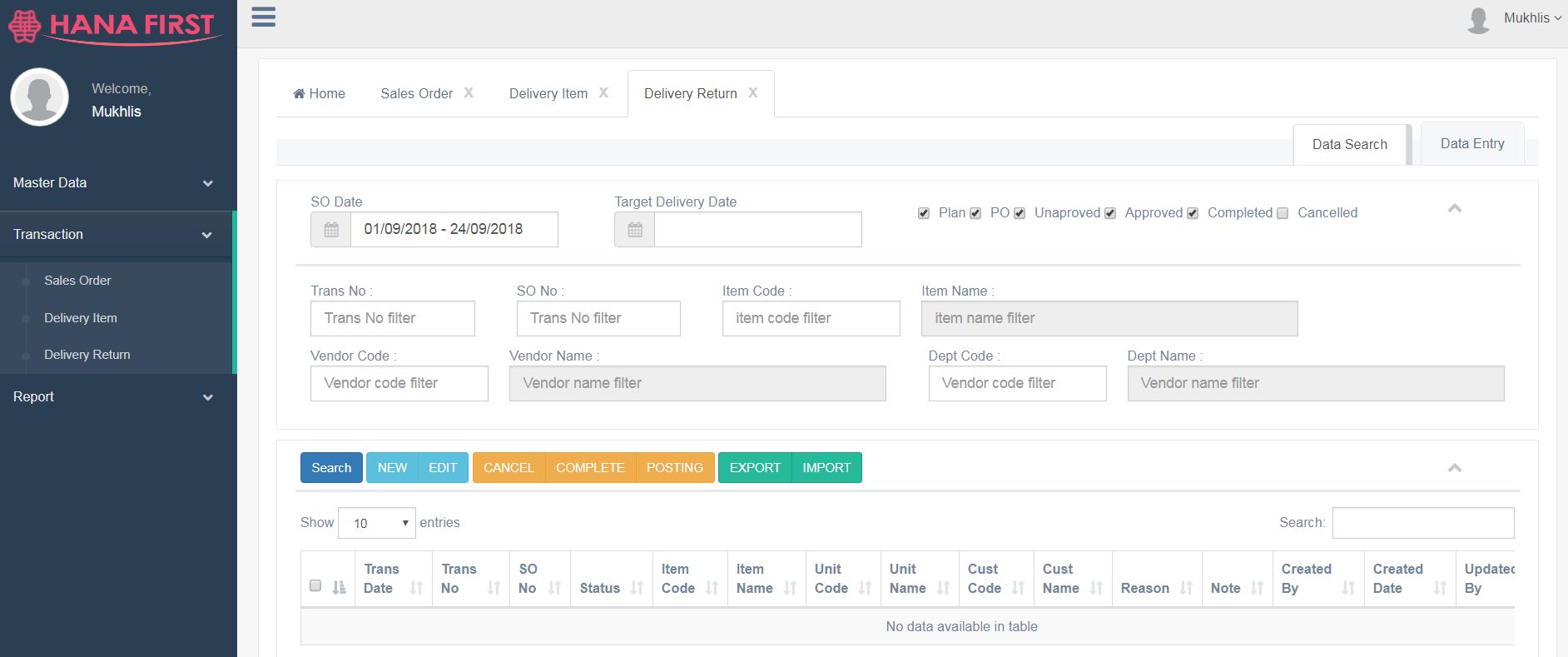

Sales Management

Orders from customers are registered, shipment registration manages order backlogs, and defective items discovered after shipment are registered as return shipments.

Sales Order / Delivery Item / Delivery Return

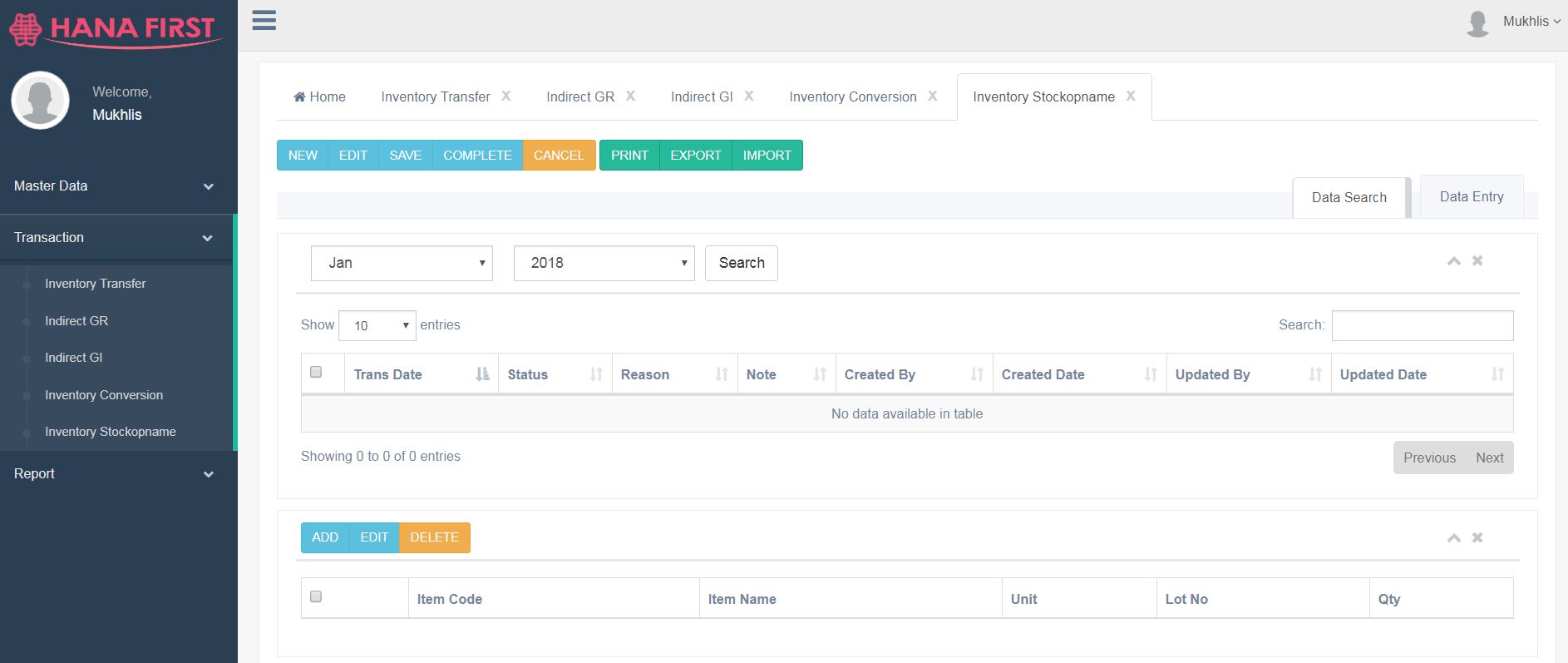

Inventory Control

Movement of goods between warehouses is handled as inventory transfer, receipt and issuance of goods as indirect entry/exit, conversion of goods as inventory conversion, and correction of theoretical inventory quantities to actual stock quantities is performed through the inventory count function.

Inventory Transfer / Indirect GI / Inventory GR / Inventory Conversion / Inventory Stockopname

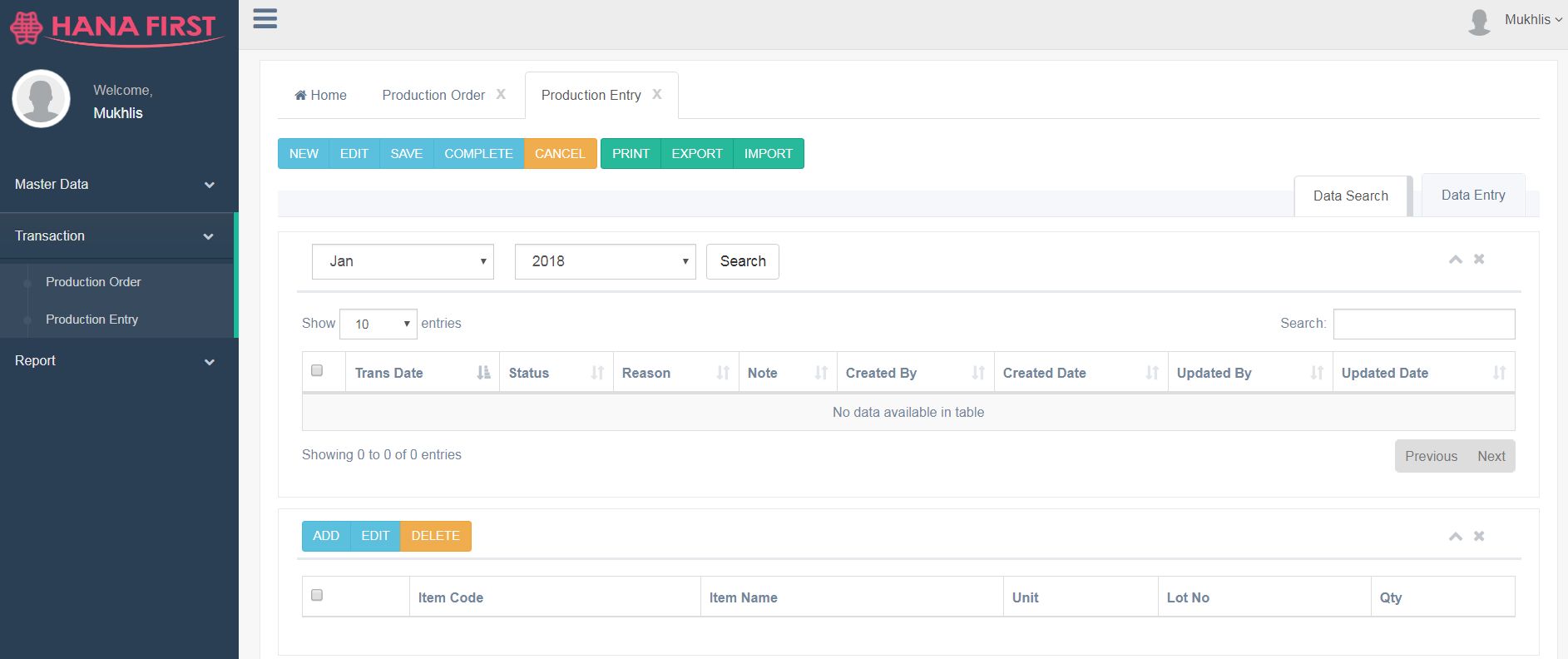

Production Control

Manufacturing instructions are issued, and production performance is recorded.

Production Order / Production Entry