Profitability improvement from an accounting perspective

It's often said in accounting that "profit and depreciation create cash," meaning that there are two sources of cash for a company: profit and depreciation.

Depreciation is a non-cash outflowing expense, and it's just playing with the numbers to show that there is actually more cash left over for depreciation than for net income on P/L, not that it physically generates cash.

Therefore, I think there are roughly four things we can do to increase cash in the face of falling sales due to the effects of the Corona pandemic.

- Increase losses and reduce taxable income (tax savings).

- Shorten the site for payment of receivables from sales and delay the site for payment of debts from cost of sales.

- Reduce cost of sales and SG&A expenses and increase core business profits (operating income)

- Increase non-operating cash receipts, such as the sale of land and buildings, and reduce non-operating cash expenditures, such as through the cancellation of internal events.

Profits are "sales - expenses" and as long as sales in your core business don't increase, you'll have to cut expenses to increase profits, but in fact, Jakarta is also cutting fixed costs by laying off employees, canceling outsourcing contracts, cutting salaries and canceling office space.

Across Indonesia, the number of employees laid off PHK (Pemutusan Hubungan Kerja) is said to have reached 7 million by April, and as a result of the brake on office relocation and expansion, the occupancy rate of new office buildings in Jakarta is said to be around 70 percent.

Profitability improvement in the supply chain

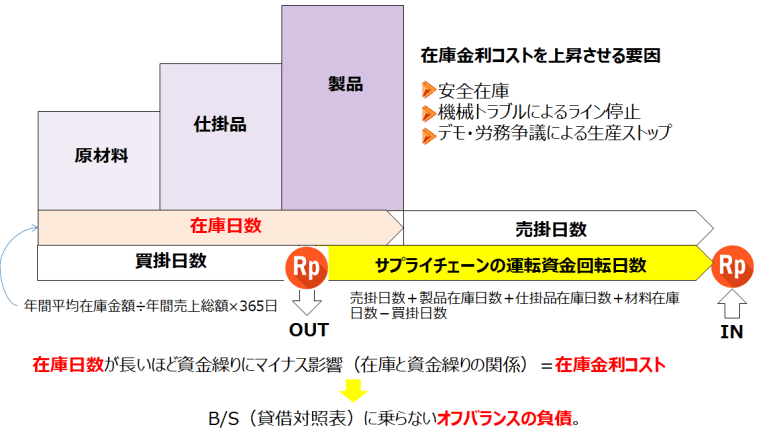

Raw materials, work-in-process, and products, which are future cash, are sitting in warehouses in the form of inventories, which put pressure on earnings in terms of negative cash flow, the opportunity loss of interest earned when cash is essentially deposited in the bank, and the interest rate on borrowing to finance raw materials.

There are two reasons to pay this inventory interest cost to have inventory in-house, the first is that the "order lead time" from receiving an order to shipping is shorter than the "manufacturing lead time" from the start of production to the end of production, so it is an insurance policy to make up the difference in lead time, the other reason is because we need it as a buffer inventory to keep the bottleneck processes that determine the productivity of the entire plant from stopping. Current situation of manufacturing industry in Indonesia I will explain based on the case about the system implementation for making the demand forecast in consideration of the supply capacity of the in-house production resource. 続きを見る

Reviewing imports from China, where there is a high supply chain risk due to economic friction between the U.S. and China and the effects of the new corona epidemic, and establishing a system that enables local procurement so that orders can be placed at the right time and orders can be received immediately.

Just-in-time production, where manufacturing starts at the same time materials arrive and shipments are made at the same time they are completed, with multi-skilled labor and the conversion of internal setups to external setups (i.e., setting up the machine in advance so as not to stop it), etc.

The production plan to increase production efficiency with a limited number of workers after a reduction in the workforce will lead to improved profitability.

Business Improvement from an IT Infrastructure Perspective

When constructing an IT infrastructure, we understand the current business flow and content, examine how to improve the problems and implement them in the system. Even though IT investments are not being made due to the Corona pandemic, business analysis and business improvement can be tackled in-house without spending a lot of money.

There are roughly only two things you need to analyze your business.

- Business Flow: Necessary to get a bird's eye view of the entire flow

- Work Details: To understand the contents of each task that make up a business that cannot be described in the business flow.

Based on the four ECRS principles (Eliminate, Combine, Rearrange and Simplify), which are standard when thinking about business improvement, we restructure the flow of business operations to achieve maximum results with minimum workload, and create a standard operation procedure (SOP).

In practice, changing the way workers do their jobs requires changes to the flow and structure of business data, but even if we use Excel for the time being, systematization is unavoidable to improve business efficiency in order to overcome the corona ravages.

We believe that post-corona pandemic corporate sites will see a trend towards paperless and IoT to minimize opportunities for physical contact and sharing of goods to minimize opportunities for viral transmission, as well as a trend towards IT adoption to review and improve existing operations. Paperlessness and IoT accelerated by corona pandemic The main purpose of paperless systems was not only to reduce the cost of paper, but also to prevent errors in posting actual data. However, with the spread of the new coronavirus, there is a need to reduce opportunities for physical contact in order to prevent infections, and the shift to IoT in manufacturing is accelerating. 続きを見る