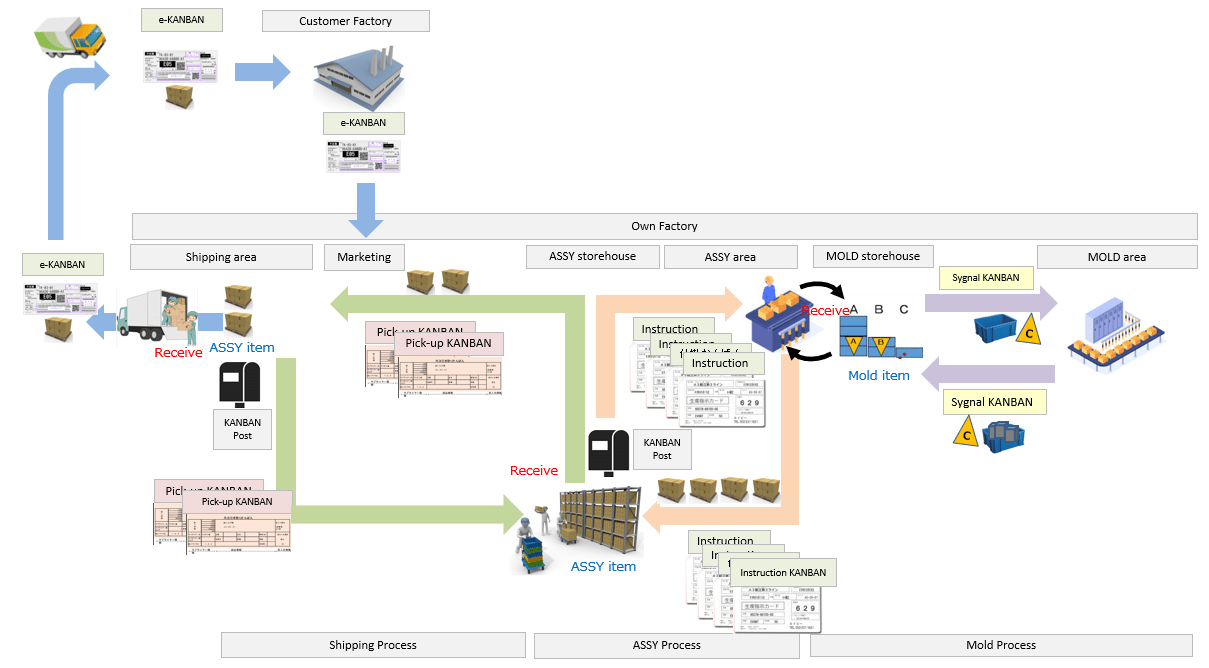

Two types of Kanban system

To separate Pick-up Kanban from Instruction Kanban

The Kanban itself is clearly divided into two categories: movement instructions for the pick-up Kanban and production instructions for the Instruction Kanban.

The e-Kanban sent by email from the customer with shipping instructions is placed in a box in the shipping area. Replace it with a pick-up kanban that is inserted, ship it together with the box to the customer (in this case, one box), and The original goods are checked with the shipping slip and e-Kanban. The replaced Pick-up Kanban remains at the Kanban post.

When a predetermined number of take-back Pick-up kanban left at the kanban post in the shipping area are accumulated (in this case, 2 kanban), they are returned to the assembly yard and replaced with Instruction Kanban that is inserted in the box, and the Instruction kanban is returned to the kanban post to pick up the 2 boxes in the shipping area.

When a predetermined number of Instruction Kanban in the assembly area are accumulated (4 Kanban in this case), they are returned to the assembly area to start assembly work.

For processes with short tact time, such as the molding process in the previous process, the forming process starts when the minimum stock is exhausted, using a signal kanban.

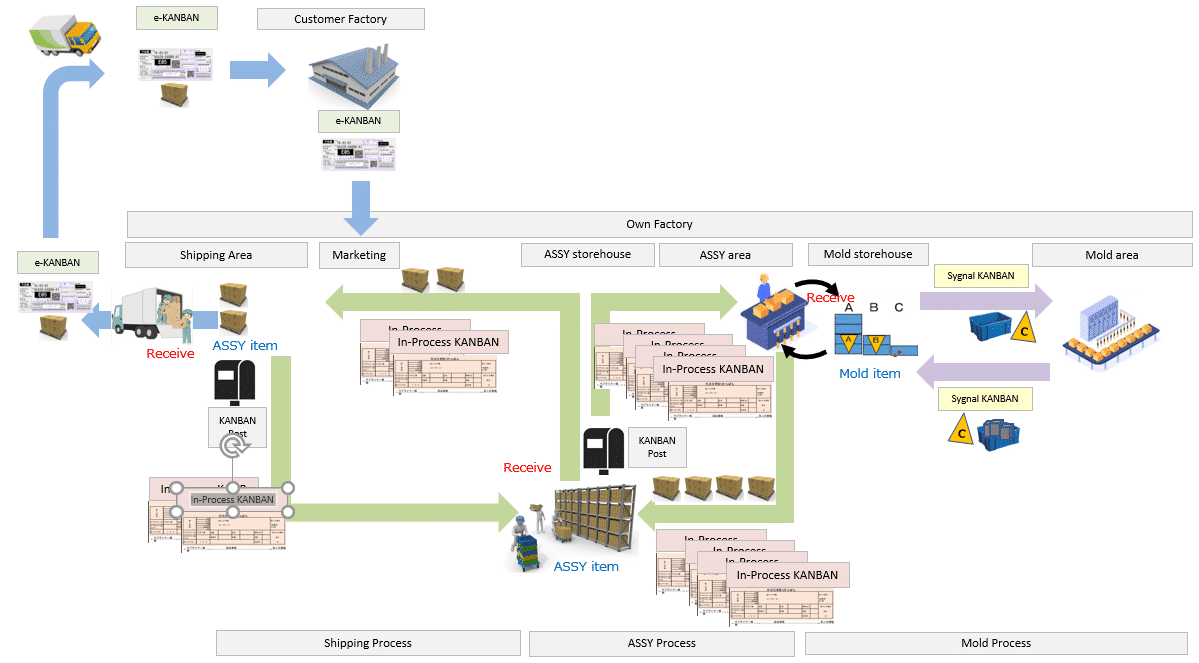

When an Pick-up kanban and an Instruction kanban are combined into an In-process kanban

Kanban is treated as an In-process kanban that rotates in the same process.

When the number of In-process Kanban left in the shipping area is accumulated, the In-process Kanban are returned to the Kanban post in the assembly area (in this case, 2 boards) and the 2 boxes are collected in the shipping area.

When the In-process kanban left on the kanban post in the assembly area, the Kanban is returned to the assembly area when the required number of Kanban have been accumulated (in this case, 4 Kanban), and assembly work begins.

The number of Kanban sheets is the total number of Kanban sheets (Kanban to be picked up and Kanban in progress) or the number of Kanban sheets in process.

- Number of boxes required per day x (Kanban L/T + processing L/T + safety stock) = 1 x (2 + 4 + 0) = 6 boxes

Toyota needs to have a plan for leveling the input to the line.

The "pull-type" kanban system, which operates autonomously on the shop floor to take only the required quantity of items from the front-It is said that the "pull-type" Kanban system, in which only the necessary items are taken from the front-end process in the required quantities and production is carried out autonomously on the shop floor, is the opposite of the "push-type" MRP production plan created by the management organization.

At the manufacturing line of Toyota's final assembly plant, which is at the top of the chain, scheduling is carefully calculated in units of time and date to determine what should be delivered and in what order.

In order to meet the input order schedule at the Toyota assembly plant, we receive several e-kanban (take-back kanban) shipping instructions every day for separate deliveries.

Because we are required to deliver what we need, as much as we need, and at the right time, our daily production orders must be leveled so that the same variety is produced in the same quantity, or else we will not be able to keep up with production preparations such as arranging personnel and reconfiguring the production line.

The Kanban system, which requires a system that can always produce the required amount of products at the required time in any process, needs to eliminate variations in production volume and product types.

If we produce 100 units today and 1 unit tomorrow, there will be a lot of waste to keep the production system running and it will be very costly.

Even if the Toyota assembly plant receives a large number of orders for the same car model, they will schedule the car models separately on the mixed flow line so as not to exceed the production capacity of their own line and that of their subcontractors.

In other words, the subcontractors do not need to create production plans because the Toyota assembly plant creates a detailed production plan for leveling out.